SZA Petrochemical Process Pump

SZA Petrochemical Process Pump is single-stage single-suction Horizontal Chemical Centrifugal pump, pump body for foot support, single-suction impeller, axial suction, radial discharge. The axial force is balanced by the front and rear mouth rings and Balance Holes. Shaft Seal Mechanical Seal can be a single-sided or double-sided balance of the container type, can also be used packing seal. Mechanical seal with cooling, flushing or sealing fluid system, sealing pipeline system according to API specification design. Suction and discharge flanges can be designed according to GB, Din, ANSI standards.

SZA Petrochemical Process Pump deliver solutions of inorganic and organic acids such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations; alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations; All kinds of liquid petrochemical products, organic compounds and other corrosive liquids.

SZA Petrochemical Process Pump deliver solutions of inorganic and organic acids such as sulfuric acid, nitric acid, hydrochloric acid and phosphoric acid at various temperatures and concentrations; alkaline solutions such as sodium hydroxide and sodium carbonate at various temperatures and concentrations; All kinds of liquid petrochemical products, organic compounds and other corrosive liquids.

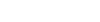

Structure Drawing of Type Sproull®SZA Pump

| 1 | Volute casing | 8 | Shaft sleeve | 15 | Shaft | 22 | Cooling water jacket | 29 | Sealing cap |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Impeller nut | 9 | Sealing cap | 16 | Bearing | 23 | Bearing frame | 30 | Shaft sleeve |

| 3 | Threaded insert | 10 | Machinery Seal | 17 | Round nut | 24 | Bearing | 31 | Pump cover |

| 4 | Impeller | 11 | Screw rings | 18 | Key | 25 | Bearing cap | 32 | Gasket |

| 5 | Impeller wear ring | 12 | Vent filter | 19 | Bearing cap | 26 | Dustproof plate | 33 | Static ring seat |

| 6 | Pump wear ring | 13 | Constant-level-oiler | 20 | Feet | 27 | Pipe | 34 | Key |

| 7 | Casing cover | 14 | Lubricating ring | 21 | Deflector | 28 | Machinery Seal |

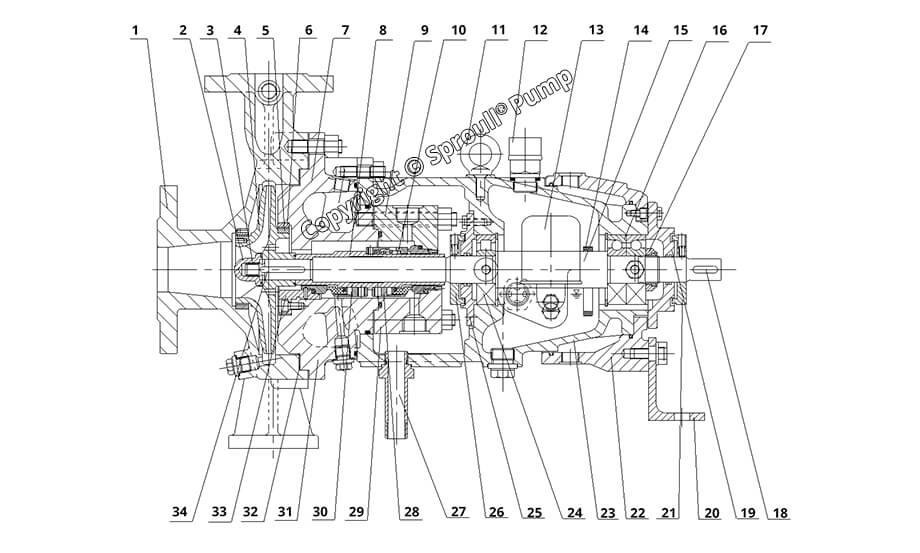

Sproull® SZA Preformance Curve(Demonstration)

| lllustrations of Model Type | |||

|---|---|---|---|

| SZA100-400 | |||

| SZA | Petrochemical Process Pump | ||

| 100 | Diameter of pump outlet | ||

| 400 | Diameter of impeller | ||

Sproull® SZA Preformance parameter list

| Type |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

|---|---|---|---|---|---|---|---|---|

| SZA25-200 | 2950 | 11.5 | 49 | 7.5 | 1475 | 5.8 | 12 | 1.5 |

| 9 | 36 | 4 | 4.6 | 8.5 | 1.1 | |||

| 5.5 | 16 | 1.5 | 3 | 4 | 1.1 | |||

| SZA40-160 | 2950 | 28 | 33 | 7.5 | 1475 | 14 | 8 | 1.5 |

| 22 | 22 | 5.5 | 11 | 5.5 | 1.1 | |||

| 20 | 16 | 3 | 9.5 | 4.5 | 1.1 | |||

| SZA50-200 | 2950 | 62 | 52 | 22 | 1475 | 31 | 13 | 3 |

| 49 | 37 | 15 | 25 | 9 | 2.2 | |||

| 43 | 28 | 11 | 22 | 7 | 1.5 | |||

| SZA80-250 | 2950 | 127 | 82 | 75 | 1475 | 64 | 20 | 11 |

| 105 | 59 | 55 | 52 | 14.5 | 5.5 | |||

| 87 | 45 | 30 | 46 | 11 | 4 | |||

| SZA100-200 | 2950 | 193 | 50 | 55 | 1475 | 95 | 12.5 | 7.5 |

| 155 | 35 | 37 | 80 | 8.5 | 5.5 | |||

| 135 | 26 | 30 | 70 | 6 | 3 | |||

| SZA150-250 | 2950 | 390 | 74 | 160 | 1475 | 195 | 18.5 | 22 |

| 355 | 62 | 110 | 180 | 16 | 18.5 | |||

| 326 | 46 | 90 | 160 | 11.5 | 11 | |||

| SZA200-250 | 2950 | 610 | 72 | 160 | 1475 | 305 | 17.5 | 30 |

| 580 | 65 | 160 | 290 | 16 | 30 | |||

| 520 | 47 | 110 | 260 | 12 | 18.5 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

||||||||

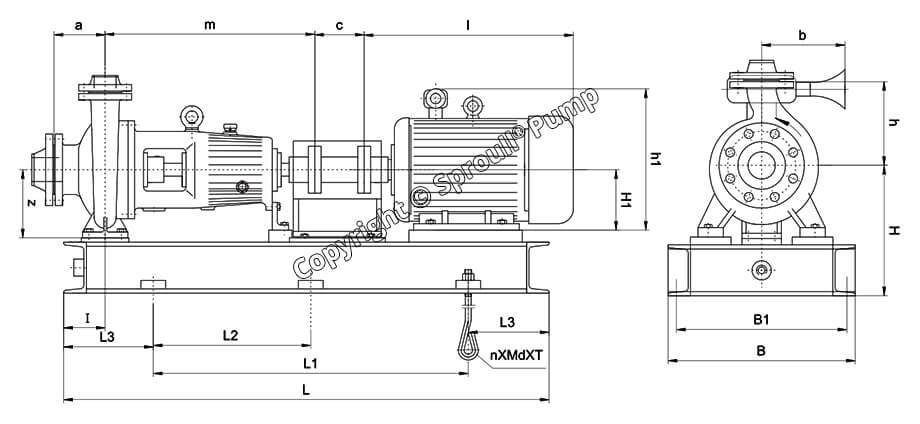

Sproull®SZA Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | m | z | h | c | l | Speed n=2950r/min | |||||||||||||

| Motor power(kW) | I | H1 | h1 | b | H | L | L1 | L2 | L3 | B | B1 | nxMdxT | |||||||

| SZA100-400 | 210 | 675 | 280 | 380 | 180 | 125 | 315 | 1900 | 450 | 1260 | 560 | 700 | 2800 | 2100 | 700 | 350 | 1050 | 1000 | 8xM24x500 |

Working Condition:

Size: 25-400mm

Capacity: up to 2600m³/h

Head: up to 250m

Speed:450-2950r/min

Operating pressures:up to 2.5MPa

Working Temperature:-80℃~ +450℃

The flow parts of petrochemical process pump are made of stainless steel 304,304L, 316,316L, CD-4MCu, 904,904L, hastelloy alloy, etc.

Design features:

The SZA series petrochemical process pump is a single-stage single-suction cantilever type rear door structure, so it is not necessary to remove the suction and discharge pipeline when the pump is repaired. After the pump cover is removed, the suspension can be pulled out together with the rotor components from the pump body, so it’s very convenient to check and repair. The rear cover plate of the impeller has a sealing ring, which can basically balance the axial force, and the residual unbalance force is borne by the thrust bearing. When the working temperature is below 250 °c, the suspension does not need to be cooled. When the working temperature is above 250 °C ~ 450 °C, the suspension is air-cooled or water-cooled. According to different conditions, part of the pump is double volute structure, the rest is single volute. Shaft seal can use packing seal, can also use single-sided or double-sided mechanical seal, and equipped with cooling, flushing or sealing fluid system. It is driven directly by electric motor and connected with electric motor by coupling.

Size: 25-400mm

Capacity: up to 2600m³/h

Head: up to 250m

Speed:450-2950r/min

Operating pressures:up to 2.5MPa

Working Temperature:-80℃~ +450℃

The flow parts of petrochemical process pump are made of stainless steel 304,304L, 316,316L, CD-4MCu, 904,904L, hastelloy alloy, etc.

Design features:

The SZA series petrochemical process pump is a single-stage single-suction cantilever type rear door structure, so it is not necessary to remove the suction and discharge pipeline when the pump is repaired. After the pump cover is removed, the suspension can be pulled out together with the rotor components from the pump body, so it’s very convenient to check and repair. The rear cover plate of the impeller has a sealing ring, which can basically balance the axial force, and the residual unbalance force is borne by the thrust bearing. When the working temperature is below 250 °c, the suspension does not need to be cooled. When the working temperature is above 250 °C ~ 450 °C, the suspension is air-cooled or water-cooled. According to different conditions, part of the pump is double volute structure, the rest is single volute. Shaft seal can use packing seal, can also use single-sided or double-sided mechanical seal, and equipped with cooling, flushing or sealing fluid system. It is driven directly by electric motor and connected with electric motor by coupling.