SZE Petrochemical Process Pump

SZE Petrochemical Process Pump is designed and manufactured according to API610 specification.The selection of pump flow components is refined. According to the working conditions, the choice of material is completely determined by the user.

SZE Petrochemical Process Pump is suitable for conveying clean or slightly polluted neutral or slightly corrosive liquid without solid particles.

SZE Petrochemical Process Pump is suitable for conveying clean or slightly polluted neutral or slightly corrosive liquid without solid particles.

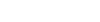

Structure Drawing of Type Sproull®SZE Pump

| 1 | Outlet flange | 4 | Wear ring | 7 | Nut | 10 | Insulation cavity |

|---|---|---|---|---|---|---|---|

| 2 | Pump casing | 5 | Bearing Protector | 8 | Impeller | 11 | Sealed cavity |

| 3 | Gasket | 6 | Shaft | 9 | Discharge line | 12 | Bearing housing |

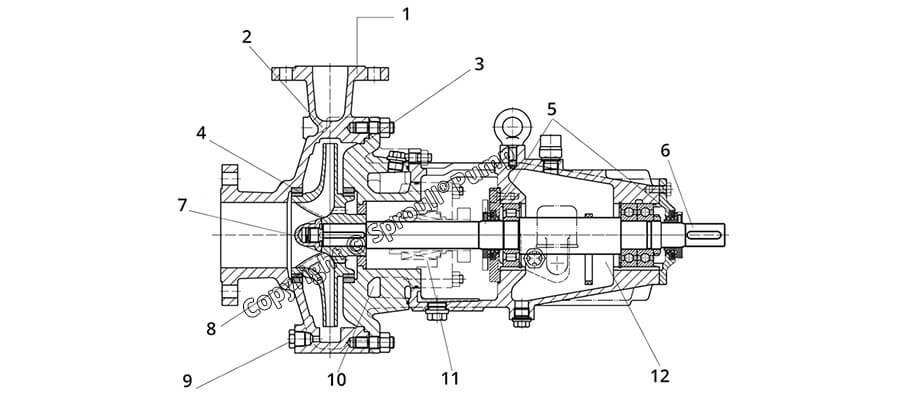

Sproull® SZE Preformance Curve(Demonstration)

| lllustrations of Model Type | |||

|---|---|---|---|

| SZE50-160 | |||

| SZE | Petrochemical Process Pump | ||

| 50 | Outlet diameter | ||

| 160 | Impeller nominal diameter | ||

Sproull® SZE Preformance parameter list(Demonstration)

| Type |

capacity Q(m³/h) |

head H(m) |

Eff η(%) |

Shaft power pa(kw) |

speed n(r/min) |

Impeller diameter(mm) | Inlet diameter(mm) | Outlet diameter(mm) |

|---|---|---|---|---|---|---|---|---|

| SZE25-200 | 6.9 | 54.9 | 36.4 | 2.84 | 2950 | 209 | 50 | 25 |

| 11.5 | 50 | 40 | 3.92 | |||||

| 13.225 | 46.1 | 39.2 | 4.24 | |||||

| SZE40-160 | 16.8 | 35.1 | 54.7 | 2.94 | 2950 | 169 | 80 | 40 |

| 28 | 32 | 60 | 4.07 | |||||

| 32.2 | 29.5 | 58.8 | 4.4 | |||||

| SZE50-315 | 26.4 | 30.7 | 48.3 | 4.57 | 1475 | 324 | 100 | 50 |

| 44 | 28 | 53 | 6.33 | |||||

| 52.8 | 25 | 51.2 | 7.03 | |||||

| SZE80-400 | 51 | 50.5 | 52.8 | 13.29 | 1475 | 409 | 100 | 80 |

| 85 | 46 | 58 | 18.37 | |||||

| 102 | 41 | 56 | 20.35 | |||||

| SZE100-250 | 138 | 84.1 | 69.7 | 45.37 | 2950 | 259 | 150 | 100 |

| 230 | 75 | 80 | 58.76 | |||||

| 264.5 | 68.6 | 78 | 63.39 | |||||

| SZE200-400 | 252 | 56.1 | 70.6 | 54.57 | 1475 | 409 | 200 | 200 |

| 420 | 50 | 81 | 70.65 | |||||

| 504 | 43.9 | 77.2 | 78.1 | |||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

||||||||

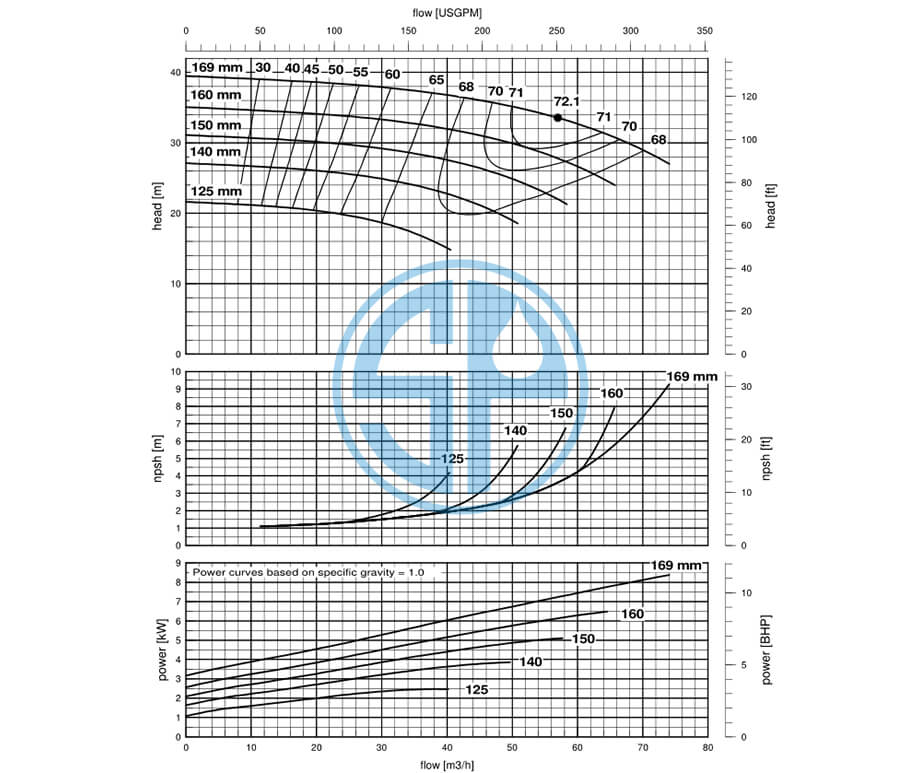

Sproull®SZE Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | L12 | L13 | |

| SZE50-160 | 165 | 560 | 140 | 839 | 230 | 160 | 20 | 80 | 180 | 300 | 600 | 1200 | 1800 |

| A1 | A2 | A3 | A4 | A5 | S1 | S2 | S3 | S4 | S5 | S6 | S7 | ||

| 80 | 40 | 15 | 20 | 20 | 255 | 255 | 950 | 260 | 1780 | 140 | 450 | ||

Working Condition:

Size: 25-400mm

Capacity: 0.5 – 3000m³/h

Head: 4 – 250m

Speed: 1470,2950r/min

Operating pressures: 2.5MPa

Working Temperature: -40℃~ +180℃

Design features:

1. The pump is a single-stage, single-suction, horizontal suspension centrifugal pump (see structure diagram).

2. The pump suction port is a horizontal axis, and the pump discharge port is a vertical center upward structure, and they are all cast together with the pump body.

3. The pump body is vortex type, radial split, foot support.

4. The impeller is integrally cast, with a rear sealing ring and a balance hole to balance the axial force of the pump. The residual axial force consists of a pair of back-to-back angular contacts ball bearings to bear.

5. The shaft seal cavity and the pump cover are cast as a whole, which can be equipped with packing seals and various mechanical seals. There is an optional water-cooling jacket outside the shaft seal cavity.

The water-cooling jacket must be equipped with special requirements or when the temperature of the conveying medium is water exceeds 66 ℃, and the temperature of carbon chloride exceeds used when over 120℃.

6. The bearing box is equipped with a set of single-row radial short cylindrical roller bearings and a set (two sets) of back-to-back thrust ball bearings. Lubricate with oil ring thin oil. The oil level is controlled simultaneously by the oil gauge (visual oil window) and the oil cup. The oil cup can also automatically adjust the oil level. The outer surface of the bearing box is cast with heat sinks, which can be air-cooled (tに120℃), and can also be cooled by fan or water (t>120℃). Suspension feet are added to the outer end of the bearing box to stabilize the pump. Operation plays a supporting role.

7. In order to easily remove the impeller, shaft, bearing, shaft seal and other parts without disassembling the suction pipeline and discharge pipeline during pump maintenance. This series of pumps uses an elongated flexible diaphragm coupling part. For safety reasons, the coupling part is also equipped with a coupling set.

8. The pump units are provided with a common base and anchor bolts.

9. Piping system; whether it is a sealed flushing piping system or a cooling water piping system, it is assembled by the pump manufacturer according to the nature and temperature of the liquid delivered.

Size: 25-400mm

Capacity: 0.5 – 3000m³/h

Head: 4 – 250m

Speed: 1470,2950r/min

Operating pressures: 2.5MPa

Working Temperature: -40℃~ +180℃

Design features:

1. The pump is a single-stage, single-suction, horizontal suspension centrifugal pump (see structure diagram).

2. The pump suction port is a horizontal axis, and the pump discharge port is a vertical center upward structure, and they are all cast together with the pump body.

3. The pump body is vortex type, radial split, foot support.

4. The impeller is integrally cast, with a rear sealing ring and a balance hole to balance the axial force of the pump. The residual axial force consists of a pair of back-to-back angular contacts ball bearings to bear.

5. The shaft seal cavity and the pump cover are cast as a whole, which can be equipped with packing seals and various mechanical seals. There is an optional water-cooling jacket outside the shaft seal cavity.

The water-cooling jacket must be equipped with special requirements or when the temperature of the conveying medium is water exceeds 66 ℃, and the temperature of carbon chloride exceeds used when over 120℃.

6. The bearing box is equipped with a set of single-row radial short cylindrical roller bearings and a set (two sets) of back-to-back thrust ball bearings. Lubricate with oil ring thin oil. The oil level is controlled simultaneously by the oil gauge (visual oil window) and the oil cup. The oil cup can also automatically adjust the oil level. The outer surface of the bearing box is cast with heat sinks, which can be air-cooled (tに120℃), and can also be cooled by fan or water (t>120℃). Suspension feet are added to the outer end of the bearing box to stabilize the pump. Operation plays a supporting role.

7. In order to easily remove the impeller, shaft, bearing, shaft seal and other parts without disassembling the suction pipeline and discharge pipeline during pump maintenance. This series of pumps uses an elongated flexible diaphragm coupling part. For safety reasons, the coupling part is also equipped with a coupling set.

8. The pump units are provided with a common base and anchor bolts.

9. Piping system; whether it is a sealed flushing piping system or a cooling water piping system, it is assembled by the pump manufacturer according to the nature and temperature of the liquid delivered.