SCZ Standard Chemical Process Pump

SCZ Standard Chemical Process Pumps are horizontal, single-stage, single-suction centrifugal pumps; their dimensions and performance comply with DIN24256/ISO5199/GB/T5656 standard.

According to ASME/ANSIB73.1M and API610, the high reliability standard process pump is innovatively designed.

SCZ Standard Chemical Process Pump can deliver low-and high-temperature liquids; deliver neutral or corrosive, clean or contain small amounts of solid particles. Specifically applied to:Chemical and petrochemistry, coal chemical, desalination, environmental engineering, chemical plants, oil refineries, thermal power plants, metallurgy, sugar, pharmaceutical, paper and pulp industries, synthetic fibres, water supply, heating and air conditioning.

According to ASME/ANSIB73.1M and API610, the high reliability standard process pump is innovatively designed.

SCZ Standard Chemical Process Pump can deliver low-and high-temperature liquids; deliver neutral or corrosive, clean or contain small amounts of solid particles. Specifically applied to:Chemical and petrochemistry, coal chemical, desalination, environmental engineering, chemical plants, oil refineries, thermal power plants, metallurgy, sugar, pharmaceutical, paper and pulp industries, synthetic fibres, water supply, heating and air conditioning.

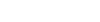

Structure Drawing of Type Sproull® SCZ Pump

| 1 | Volute casing | 7 | Casing cover | 13 | Bearing bracket | 19 | Deflector | 25 | Circlip |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Impeller nut | 8 | Double mechanical seal | 14 | Shaft | 20 | Antifriction bearing | 26 | KeyBearing cover |

| 3 | Casing cover ring | 9 | Sealing cover | 15 | Collar disc | 21 | Sight glass | 27 | key |

| 4 | O-ring | 10 | Shaft sleeve | 16 | key | 22 | Constant level oiler | ||

| 5 | O-ring | 11 | Bearing cover | 17 | Gasket | 23 | Circlip | ||

| 6 | Impeller | 12 | Antifriction bearing | 18 | Singel mechanical seal | 24 | Antifriction bearing |

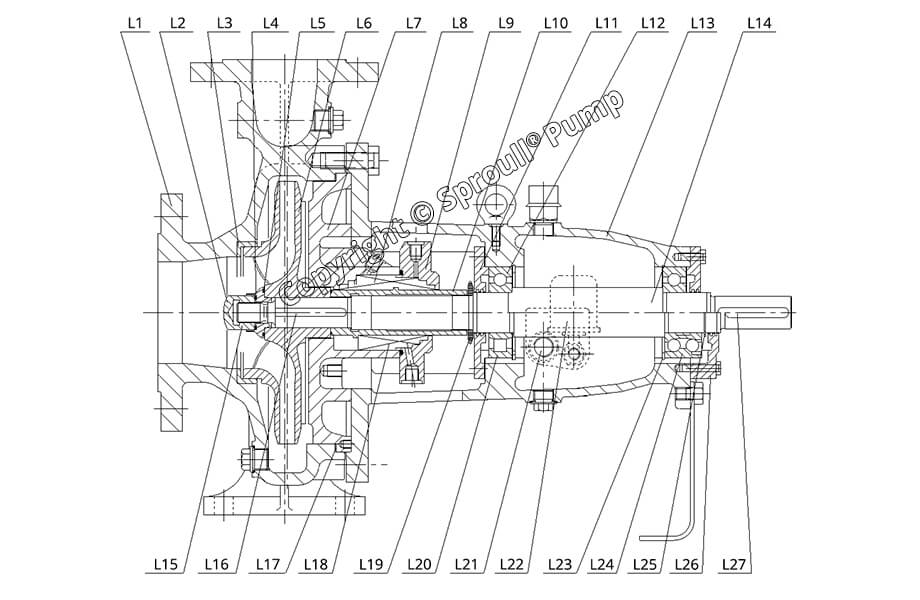

Sproull® SCZ Preformance Curve(Demonstration)

| lllustrations of Model Type | |||

|---|---|---|---|

| SCZ50-200 | |||

| SCZ | Standard Chemical Process Pump | ||

| 50 | Outlet diameter(mm) | ||

| 200 | Impeller nominal diameter(mm) | ||

Sproull® SCZ Preformance parameter list

| Type |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

|---|---|---|---|---|---|---|---|---|

| SCZ32-250 | 1450 | 8 | 11 | 2.2 | 2900 | 15 | 50 | 7.5 |

| 9 | 15 | 2.2 | 18 | 65 | 11 | |||

| 11 | 20 | 2.2 | 20 | 85 | 15 | |||

| SCZ40-160 | 1450 | 12 | 4 | 1.1 | 2900 | 14 | 18 | 3 |

| 14 | 6 | 1.1 | 16 | 26 | 5.5 | |||

| 15 | 8 | 1.1 | 30 | 34 | 7.5 | |||

| SCZ50-160 | 1450 | 20 | 4 | 1.1 | 2900 | 40 | 18 | 5.5 |

| 24 | 6 | 1.1 | 46 | 26 | 5.5 | |||

| 30 | 8 | 1.5 | 55 | 34 | 11 | |||

| SCZ65-200 | 1450 | 36 | 7 | 2.2 | 2900 | 70 | 30 | 11 |

| 42 | 10 | 3 | 90 | 40 | 18.5 | |||

| 50 | 13 | 4 | 100 | 54 | 22 | |||

| SCZ80-250 | 1450 | 70 | 11 | 5.5 | 2900 | 130 | 47 | 30 |

| 85 | 17 | 5.5 | 170 | 70 | 45 | |||

| 90 | 20 | 11 | 180 | 75 | 55 | |||

| SCZ100-315 | 1450 | 90 | 21 | 15 | 2900 | 200 | 85 | 75 |

| 100 | 26 | 15 | 230 | 100 | 110 | |||

| 132 | 32 | 30 | 270 | 135 | 160 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

||||||||

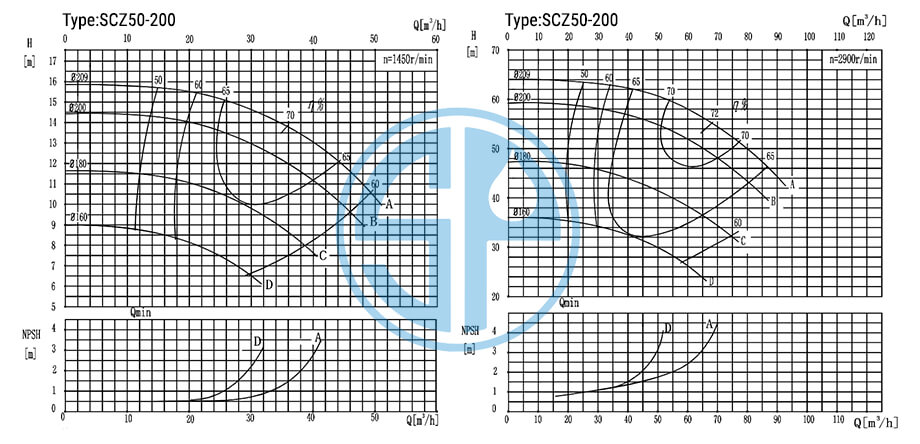

Sproull® SCZ Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ΦDs | ΦDs1 | ΦD1 | b1 | n-Φd1 | ΦDd | ΦDd2 | ΦD2 | b2 | n-Φd2 | a | h | h1 | Motor frame number(180M) | ||||||||||

| L | L1 | L2 | L3 | L4 | B | B1 | n-Md×1 | H | I | ||||||||||||||

| SCZ50-200 | 80 | 160 | 200 | 24 | 8-Φd18 | 50 | 125 | 165 | 20 | 4-Φd18 | 100 | 160 | 200 | 1295 | 1250 | 840 | 205 | 390 | 350 | 4-M12×250 | 155 | 75 | |

Working Condition:

Size:32-300mm

Capacity: up to 2000m³/h

Head: up to 160m

Speed:1450r/min,2900r/min.

Operating pressures:up to 2.5MPa

Working Temperature:-80℃~ +180℃

Design features:

•CFD and PIV are used to optimize the hydraulic model design.

•Impeller anti-cavitation design, low cavitation allowance.

•Self-exhaust of end-suction Radial Shell.

•Volute casing has single volute and double volute design, balance the radial force, reduce vibration.

•Standard elongated metal diaphragm coupling design, light weight, good compensation.

•Pump Shell Corrosion Allowance, corrosion allowance 3mm design.

•Mechanical Seal (in accordance with ISO 3069 standard seal cavity design) can be equipped with single-face mechanical seal, double-face mechanical seal.

Size:32-300mm

Capacity: up to 2000m³/h

Head: up to 160m

Speed:1450r/min,2900r/min.

Operating pressures:up to 2.5MPa

Working Temperature:-80℃~ +180℃

Design features:

•CFD and PIV are used to optimize the hydraulic model design.

•Impeller anti-cavitation design, low cavitation allowance.

•Self-exhaust of end-suction Radial Shell.

•Volute casing has single volute and double volute design, balance the radial force, reduce vibration.

•Standard elongated metal diaphragm coupling design, light weight, good compensation.

•Pump Shell Corrosion Allowance, corrosion allowance 3mm design.

•Mechanical Seal (in accordance with ISO 3069 standard seal cavity design) can be equipped with single-face mechanical seal, double-face mechanical seal.