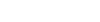

SDY Self-balancing Multistage Pump

SDY Self-balancing Multistage Pump is a horizontal single suction multistage centrifugal pump designed by API610 standard, with advantages of high efficiency, wide performance, steady and safety opertion, low noise, long worklife, easy installation etc. It can transport the medium with solid particles (the particle size should me less than quarter of the impeller channel), and the pump can use different materials, seal type, adding cooling system for delivering clean water, hot water, boiler feed water, corrosive liquids, oils, and abrasive medium etc.

SDY Self-balancing Multistage Pump can deliver oil or petroleum product without solids and viscosity less than 120 centipoises.

SDY Self-balancing Multistage Pump can deliver oil or petroleum product without solids and viscosity less than 120 centipoises.

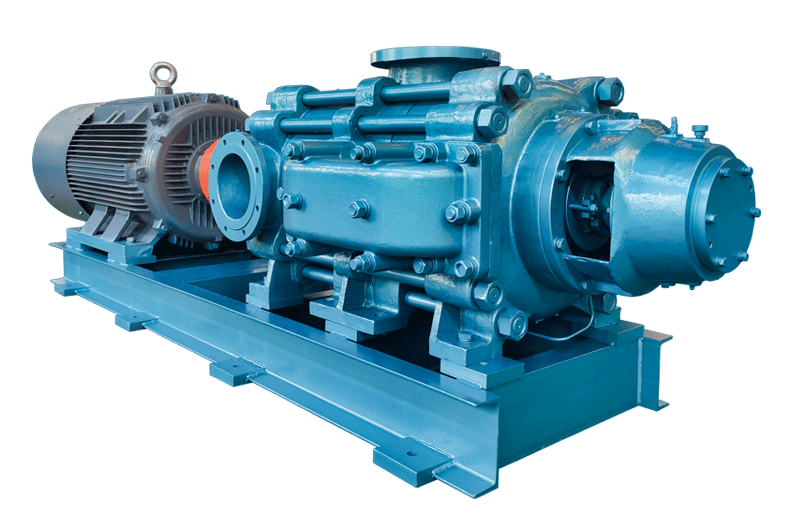

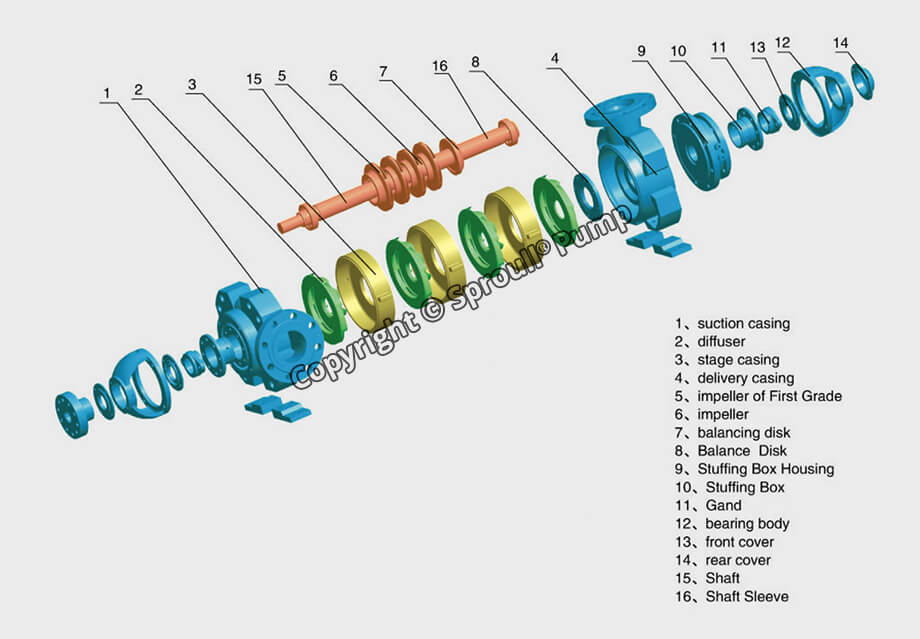

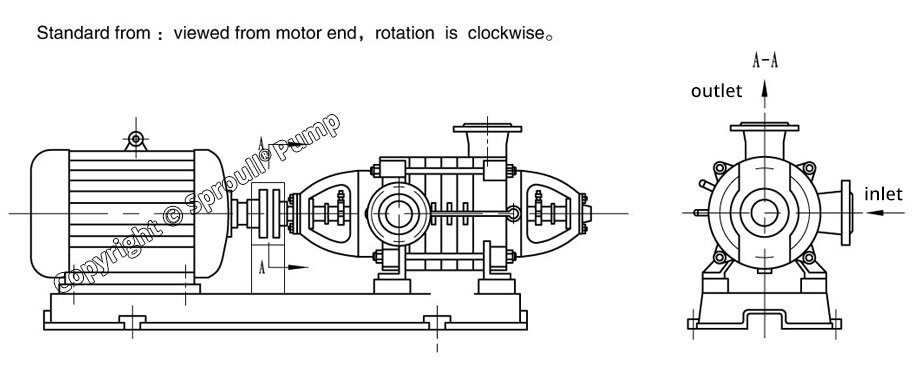

Structure Drawing of Type Sproull® SDY Pump

| 1 | Coupling | 5 | Bolt | 9 | Middle section | 13 | Outlet section | 17 | Balance plate |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Rolling bearing | 6 | Inlet section | 10 | Guide vane | 14 | Balance set | 18 | Water sealing pipe |

| 3 | Rolling bearing part | 7 | Wearing ring | 11 | Balance water pipe part | 15 | Balance ring | 19 | Packing |

| 4 | Shaft | 8 | Impeller | 12 | Guide vane sleeve | 16 | Stuffing box body | 20 | Packing gland |

Rotation Direction

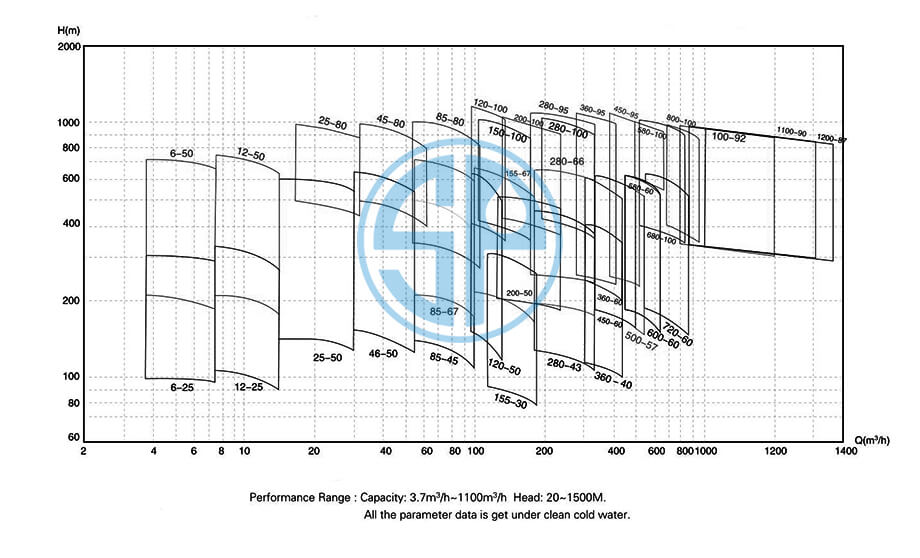

Sproull® SDY Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| SDY85-45×9 | |||

| SDY | Self-balancing multi-stage anti-wear pumps | ||

| 85 | Rated Flow is 85m³/h | ||

| 45 | Rated Head for 1 Stage is 45m | ||

| 9 | Number of stage for Pump is 9 stages | ||

Sproull® SDY Preformance parameter list(Demonstration)

| Type | Number of stage |

Capacity m³/h |

Head m |

Speed n(r/min) |

Eff η(%) |

Shaft power pa(kw) |

Motor power kw |

NPSH r(m) |

Impeller Dia. Mm |

|---|---|---|---|---|---|---|---|---|---|

| SDY1100-85 | 3 | 850 | 267 | 1450 | 82 | 754.2 | 1250 | 7.0 | 550 |

| 1100 | 255 | 84 | 910 | ||||||

| 1350 | 221 | 78 | 1042.3 | ||||||

| 4 | 850 | 352 | 1450 | 82 | 994.3 | 1600 | 7.0 | 550 | |

| 1100 | 340 | 84 | 1213.3 | ||||||

| 1350 | 306 | 78 | 1443.2 | ||||||

| 5 | 850 | 437 | 1450 | 82 | 1234.4 | 2000 | 7.0 | 550 | |

| 1100 | 425 | 84 | 1516.6 | ||||||

| 1350 | 391 | 78 | 1844.1 | ||||||

| 6 | 850 | 500 | 1450 | 82 | 1474.5 | 2500 | 7.0 | 550 | |

| 1100 | 510 | 84 | 1820 | ||||||

| 1350 | 476 | 78 | 2245 | ||||||

| 7 | 850 | 607 | 1450 | 82 | 1714.6 | 3150 | 7.0 | 550 | |

| 1100 | 595 | 84 | 2123.2 | ||||||

| 1350 | 561 | 78 | 2645.9 | ||||||

| 8 | 850 | 692 | 1450 | 82 | 1954.7 | 3550 | 7.0 | 550 | |

| 1100 | 680 | 84 | 2426.5 | ||||||

| 1350 | 646 | 78 | 3046.8 | ||||||

| 9 | 850 | 777 | 1450 | 82 | 2194.8 | 4000 | 7.0 | 550 | |

| 1100 | 765 | 84 | 2730 | ||||||

| 1350 | 731 | 78 | 3447.6 | ||||||

| 10 | 850 | 862 | 1450 | 82 | 2435 | 4500 | 7.0 | 550 | |

| 1100 | 850 | 84 | 3266.5 | ||||||

| 1350 | 816 | 78 | 3848.5 | ||||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||||

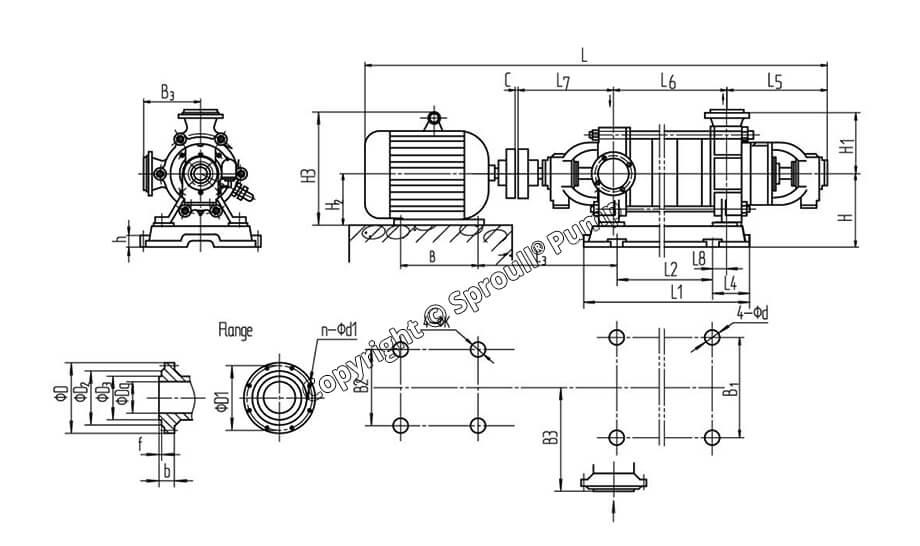

Sproull® SDY Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Motor Power (kw) |

L | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | C | B | B1 | B2 | B3 | H | H1 | H2 | H3 | h | Φd | ΦK | |

| SDY85-45×9 | 160 | 2700 | 900 | 525 | 816 | 190 | 304 | 721 | 340 | 98 | 4 | 457 | 520 | 510 | 250 | 345 | 250 | 315 | 930 | 40 | 26 | 28 |

Working Condition:

Capacity: 3-1800 m³/h

Head: 50-960 m

Speed:2950,1480 r/min

Working Temperature:0 ℃~ 80 ℃

Design features:

• With symmetrically arranged impeller rotor components, axial forces generated by all levels of symmetrical impellers forces offset each other and automatic balancing of huge axial thrust within pump cavity can be realized without the balance disc structure.

• Unique throtting and pressure reduction devices, odd-level balancing device

• Using advanced hydraulic model, independent R&D enery efficient products, Good centering of impeller and guide vane channel and efficiency will not significantly drop as balancing disc wears and rotor components move forward. No leakage of balancing water reduces loss of volume and improves pump efficiency and pump efficiency is on average 2-5% higher than normal pumps

• By canceling easy-failing balancing disc, pump reliability is greatly improved, maintenance frequency and maintenance cost are reduced

• By adopting precision casting and unique throttling and pressure reducing devices for auxiliary support pump vibration and noise are greatly reduced and service life is prolonged

• Excellent hydraulic model and design, unique first stage double suction impeller, forging casting, reliable anti-abrasive materials make sure the pump with excellent NPSH, pump work steady, no noise and users do not need to add preposition pump or inrease the height of the inlet chest

• No axial clearances when pump working and stop.

• It can change mechanical seal, bearing without disassemble the inlet/outlet pipes.

• Forging casting spare parts can save the maintenance cost

• No balance device make pump more wider application.

Capacity: 3-1800 m³/h

Head: 50-960 m

Speed:2950,1480 r/min

Working Temperature:0 ℃~ 80 ℃

Design features:

• With symmetrically arranged impeller rotor components, axial forces generated by all levels of symmetrical impellers forces offset each other and automatic balancing of huge axial thrust within pump cavity can be realized without the balance disc structure.

• Unique throtting and pressure reduction devices, odd-level balancing device

• Using advanced hydraulic model, independent R&D enery efficient products, Good centering of impeller and guide vane channel and efficiency will not significantly drop as balancing disc wears and rotor components move forward. No leakage of balancing water reduces loss of volume and improves pump efficiency and pump efficiency is on average 2-5% higher than normal pumps

• By canceling easy-failing balancing disc, pump reliability is greatly improved, maintenance frequency and maintenance cost are reduced

• By adopting precision casting and unique throttling and pressure reducing devices for auxiliary support pump vibration and noise are greatly reduced and service life is prolonged

• Excellent hydraulic model and design, unique first stage double suction impeller, forging casting, reliable anti-abrasive materials make sure the pump with excellent NPSH, pump work steady, no noise and users do not need to add preposition pump or inrease the height of the inlet chest

• No axial clearances when pump working and stop.

• It can change mechanical seal, bearing without disassemble the inlet/outlet pipes.

• Forging casting spare parts can save the maintenance cost

• No balance device make pump more wider application.