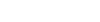

SDG Mine Dewatering Multistage Pump

SDG Mine Dewatering Multistage Pump is self-balancing multi-stage anti-wear pumps, which adopt the hydraulic model recommended by the state for high-efficiency energy-saving product. It can be used for transporting clear water without solid particles (abrasives), suspended matter or other liquids with physical and chemical properties similar to clear water. It can also be used to transport hot water,oil, corrosive or abrasive media by changing the material of the pump (or the material of the flow passage part of the pump), sealing form and increasing the cooling system.

The utility model has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long service life, convenient installation and maintenance, etc.

SDG Mine Dewatering Multistage Pump apply to drainage works in steel works and mine, it is intended to deliver mine drainage and other sewage whose solid content is not exceed 1.5% and particle is not exceed 1.3 mm.

The utility model has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long service life, convenient installation and maintenance, etc.

SDG Mine Dewatering Multistage Pump apply to drainage works in steel works and mine, it is intended to deliver mine drainage and other sewage whose solid content is not exceed 1.5% and particle is not exceed 1.3 mm.

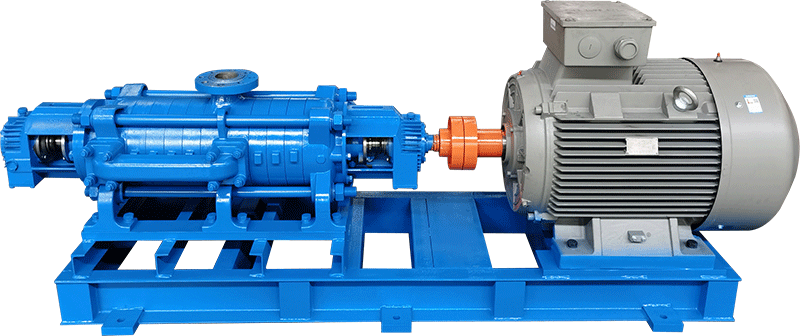

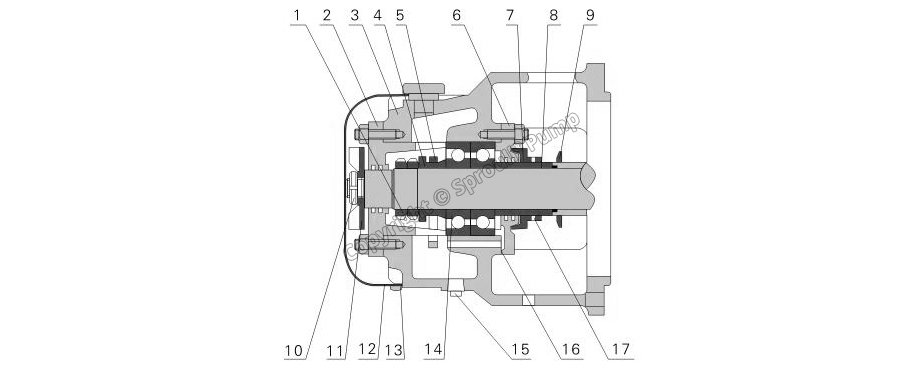

Structure Drawing of Type Sproull® SDG Pump

| 1 | Coupling Assembly | 8 | Packing | 15 | Inter-stage Bushing | 22 | Tie bolt | 29 | O-ring |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Key | 9 | Lantern Ring | 16 | Wear ring | 23 | Gasket | 30 | O-ring |

| 3 | Rotating Assembly | 10 | Cooling Chamber Cover | 17 | Discharge Diffuser | 24 | 2nd Suction Casing | ||

| 4 | Bearing Housing A Assembly | 11 | Suction Casing | 18 | Discharge Casing | 25 | Air Release Valve | ||

| 5 | Stud | 12 | Wear ring | 19 | Orifice sleeve | 26 | Bearing Housing B Assembly | ||

| 6 | Nut | 13 | Diffuser | 20 | Dowel Pin | 27 | Stud&Nut | ||

| 7 | Packing Gland | 14 | Stage casing | 21 | Seal Flush Pipe Assembly | 28 | Hexagon Socket Head Cap Screw |

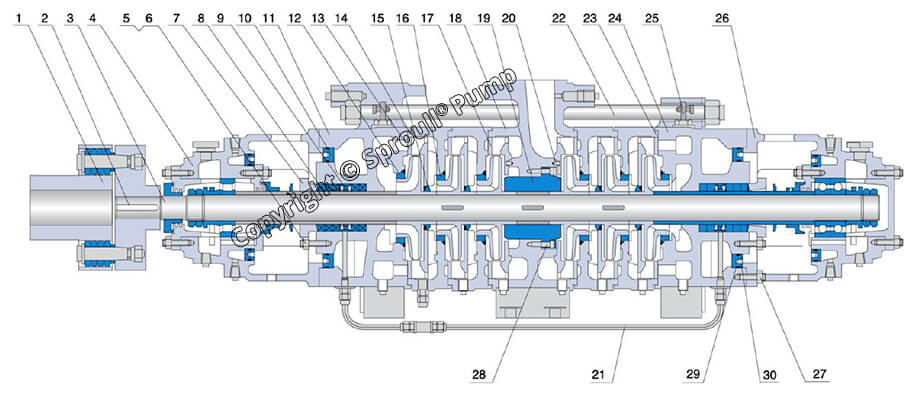

Bearing Housing A Assembly

| 1 | Bearing Cover Sealing | 5 | Oil Ring | 9 | Flinger | 13 | Gasket |

|---|---|---|---|---|---|---|---|

| 2 | Bearing End Cover A | 6 | Bearing End Cover B | 10 | Locknut | 14 | Screw |

| 3 | Bearing Housing | 7 | Bearing Cover Sealing | 11 | plug pad 1/4 | ||

| 4 | Oil Ring Sleeve | 8 | Adjustive sleeve A | 12 | cylindrical roller bearing |

Bearing Housing B Assembly

| 1 | Locknut | 5 | Oil Ring | 9 | Flinger | 13 | Screw | 17 | Screw |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Bearing End Cover C | 6 | Bearing End Cover D | 10 | Small Locknut | 14 | Angular contact ball bearing | ||

| 3 | Bearing Housing | 7 | Bearing Cover Sealing | 11 | Fan | 15 | Plug cap | ||

| 4 | Oil Ring Sleeve | 8 | Adjustive sleeve | 12 | Fan Guard | 16 | Gasket |

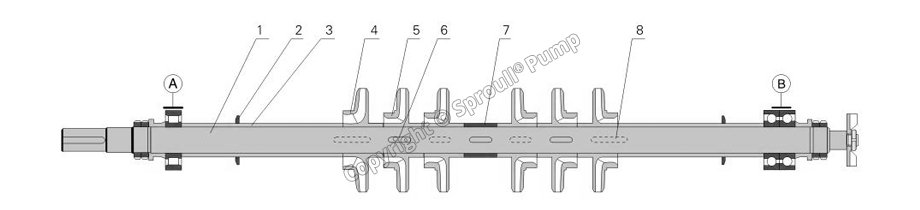

Rotating Element

| 1 | Shaft | 3 | Sealing Sleeve | 5 | Impeller | 7 | Throttle Bushing |

|---|---|---|---|---|---|---|---|

| 2 | O-ring | 4 | 1st impeller | 6 | Key | 8 | Key |

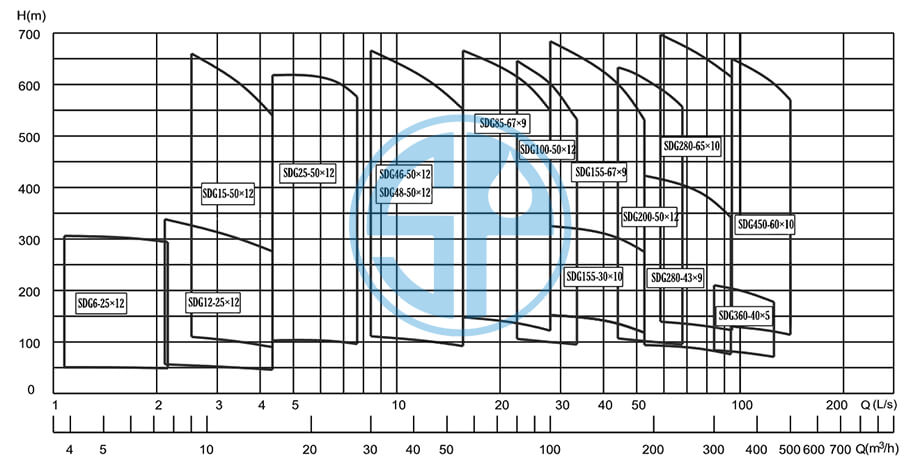

Sproull® SDG Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| SDG1100-95×4 | |||

| SDG | Mine Dewatering Multistage Pump | ||

| 1100 | Rated Flow is 1100m³/h | ||

| 95 | Rated Head for 1 Stage is 95m | ||

| 4 | Number of stage for Pump is 4 stages | ||

Sproull® SDG Preformance parameter list(Demonstration)

| Type | Number of stage |

Capacity m³/h |

Head m |

Speed n(r/min) |

Eff η(%) |

Shaft power pa(kw) |

Motor power kw |

NPSH r(m) |

Impeller Dia. Mm |

|---|---|---|---|---|---|---|---|---|---|

| SDG500-57 | 3 | 450 | 125 | 1480 | 81 | 272.6 | 355 | 4.4 | 430 |

| 500 | 138.9 | 82 | 284.1 | 5 | |||||

| 550 | 152.7 | 80 | 303.7 | 5.8 | |||||

| 4 | 450 | 125 | 1480 | 81 | 363.5 | 450 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 378.8 | 5 | |||||

| 550 | 152.7 | 80 | 404.9 | 5.8 | |||||

| 5 | 450 | 125 | 1480 | 81 | 454.4 | 630 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 473.5 | 5 | |||||

| 550 | 152.7 | 80 | 506.3 | 5.8 | |||||

| 6 | 450 | 125 | 1480 | 81 | 545.3 | 710 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 568.2 | 5 | |||||

| 550 | 152.7 | 80 | 607.4 | 5.8 | |||||

| 7 | 450 | 125 | 1480 | 81 | 636.1 | 800 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 662.9 | 5 | |||||

| 550 | 152.7 | 80 | 708.6 | 5.8 | |||||

| 8 | 450 | 125 | 1480 | 81 | 727 | 1000 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 757.6 | 5 | |||||

| 550 | 152.7 | 80 | 809.8 | 5.8 | |||||

| 9 | 450 | 125 | 1480 | 81 | 817.9 | 1120 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 852.3 | 5 | |||||

| 550 | 152.7 | 80 | 911 | 5.8 | |||||

| 10 | 450 | 125 | 1480 | 81 | 908.8 | 1250 | 4.4 | 430 | |

| 500 | 138.9 | 82 | 947 | 5 | |||||

| 550 | 152.7 | 80 | 1012.3 | 5.8 | |||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||||

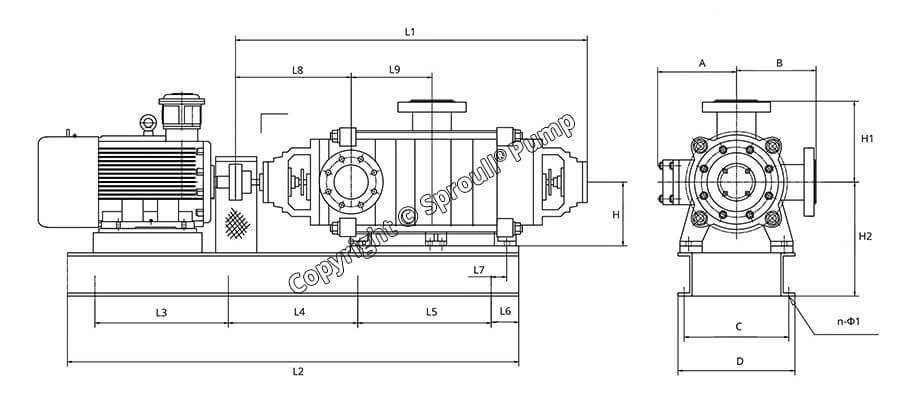

Sproull® SDG Installation Drawing(Demonstration)

| Type | Motor | Installation Dimensions(mm) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | A | B | C | D | H | H1 | H2 | n-Φ1 | inlet flange | outlet flange | |||||

| power(kw) | volt | ||||||||||||||||||||||

| SDG1100-95×4 | 355 | 380 | 2662 | 3300 | 970 | 970 | 970 | 195 | 110 | 637 | 823 | 950 | 675 | 1040 | 1130 | 600 | 675 | 910 | 8-Φ26 | DN350 | DN300 | ||

Working Condition:

Capacity: 3.7-1350 m³/h

Head: 70-1800 m

Speed:2950,1480 r/min

Power:5.5-4500kw

Design features:

Capacity: 3.7-1350 m³/h

Head: 70-1800 m

Speed:2950,1480 r/min

Power:5.5-4500kw

Design features:

• High pressure, High head, Long distance transporting

• Strong wear resistance materials

• High efficiency, wide performance range

• Operation safely and stably, low noise

• Convenient installation and easy maintenance

• Long service life, reliable performance