SU Multistage Pump can transport water without solid particles or the liquids which the chemical and physical feature are similar with water and temperature ≤ 80℃, It is widely used for delivering water in urban water project,plant water supply, irrigation and mine etc.

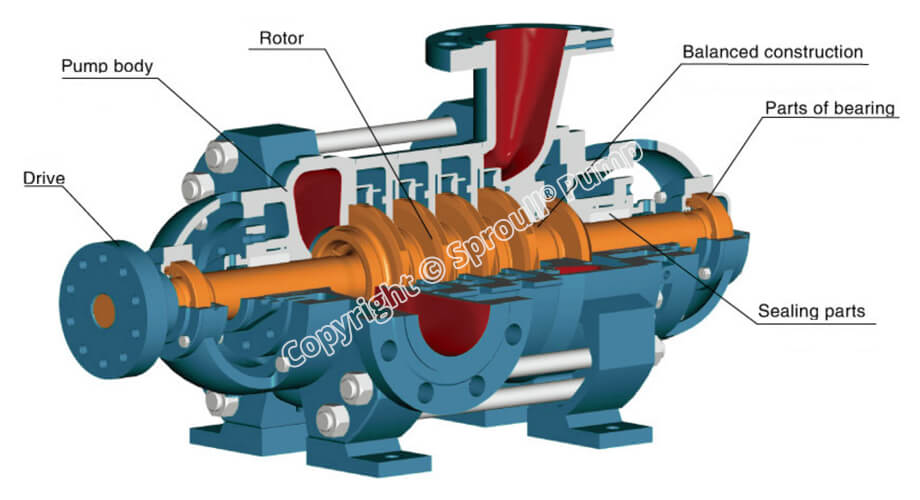

Structure Drawing of Type Sproull® SU Pump

| 1 | Suction section | 5 | Bearing support | 9 | Wearing ring | 13 | Balance ring |

|---|---|---|---|---|---|---|---|

| 2 | Outlet section | 6 | Shaft sleeve | 10 | Impeller | 14 | Balance disk |

| 3 | Tighten bolt | 7 | Shaft seal | 11 | Guide vane | 15 | Shaft |

| 4 | Shaft | 8 | Middle section | 12 | Return water pipe |

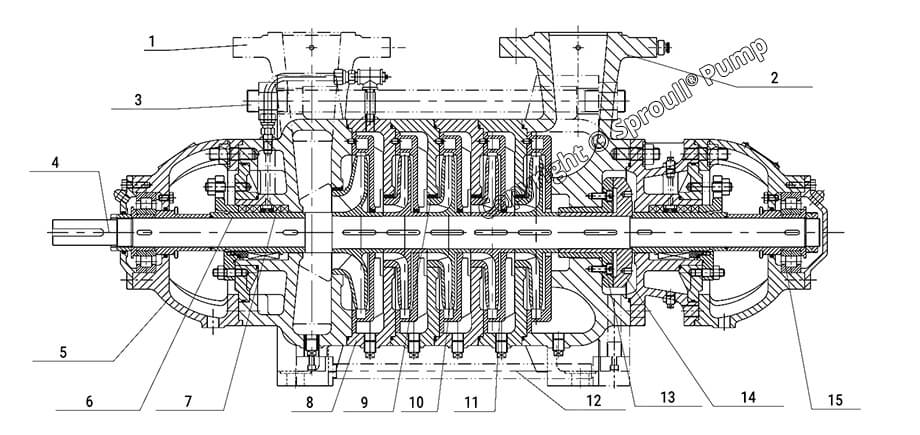

Sproull® SU Preformance Curve(Demonstration)

| lllustrations of Model Type | |||

|---|---|---|---|

| SU46-50×6 | |||

| SU | Horizontal multi-stage section centrifugal pump | ||

| 46 | Rated Flow is 46m³/h | ||

| 50 | Rated Head for 1 Stage is 50m | ||

| 6 | Number of stage for Pump is 6 stages | ||

Sproull® SU Preformance parameter list(Demonstration)

| Type | Number of stage |

Capacity m³/h |

Head m |

Speed n(r/min) |

Eff η(%) |

Shaft power pa(kw) |

Motor power kw |

NPSH r(m) |

Impeller Dia. Mm |

|---|---|---|---|---|---|---|---|---|---|

| SU46-50 | 3 | 30 | 166.5 | 2950 | 61 | 22.29 | 37 | 2.5 | 210 |

| 46 | 150 | 70 | 26.84 | 2.8 | |||||

| 55 | 138 | 71 | 29.11 | 3.2 | |||||

| 4 | 30 | 222 | 2950 | 61 | 29.73 | 45 | 2.5 | 210 | |

| 46 | 200 | 70 | 35.79 | 2.8 | |||||

| 55 | 184 | 71 | 38.81 | 3.2 | |||||

| 5 | 30 | 277.5 | 2950 | 61 | 37.16 | 55 | 2.5 | 210 | |

| 46 | 250 | 70 | 44.74 | 2.8 | |||||

| 55 | 230 | 71 | 48.52 | 3.2 | |||||

| 6 | 30 | 333 | 2950 | 61 | 44.59 | 75 | 2.5 | 210 | |

| 46 | 300 | 70 | 53.68 | 2.8 | |||||

| 55 | 276 | 71 | 58.22 | 3.2 | |||||

| 7 | 30 | 388.5 | 2950 | 61 | 52.03 | 90 | 2.5 | 210 | |

| 46 | 350 | 70 | 62.63 | 2.8 | |||||

| 55 | 322 | 71 | 67.92 | 3.2 | |||||

| 8 | 30 | 444 | 2950 | 61 | 59.46 | 90 | 2.5 | 210 | |

| 46 | 400 | 70 | 71.58 | 2.8 | |||||

| 55 | 368 | 71 | 77.63 | 3.2 | |||||

| 9 | 30 | 499.5 | 2950 | 61 | 66.89 | 110 | 2.5 | 210 | |

| 46 | 450 | 70 | 80.53 | 2.8 | |||||

| 55 | 414 | 71 | 87.33 | 3.2 | |||||

| 10 | 30 | 555 | 2950 | 61 | 74.33 | 132 | 2.5 | 210 | |

| 46 | 500 | 70 | 89.48 | 2.8 | |||||

| 55 | 460 | 71 | 97.04 | 3.2 | |||||

| 11 | 30 | 610.5 | 2950 | 61 | 81.76 | 132 | 2.5 | 210 | |

| 46 | 550 | 70 | 98.42 | 2.8 | |||||

| 55 | 506 | 71 | 106.74 | 3.2 | |||||

| 12 | 30 | 666 | 2950 | 61 | 89.19 | 160 | 2.5 | 210 | |

| 46 | 600 | 70 | 107.37 | 2.8 | |||||

| 55 | 552 | 71 | 116.45 | 3.2 | |||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||||

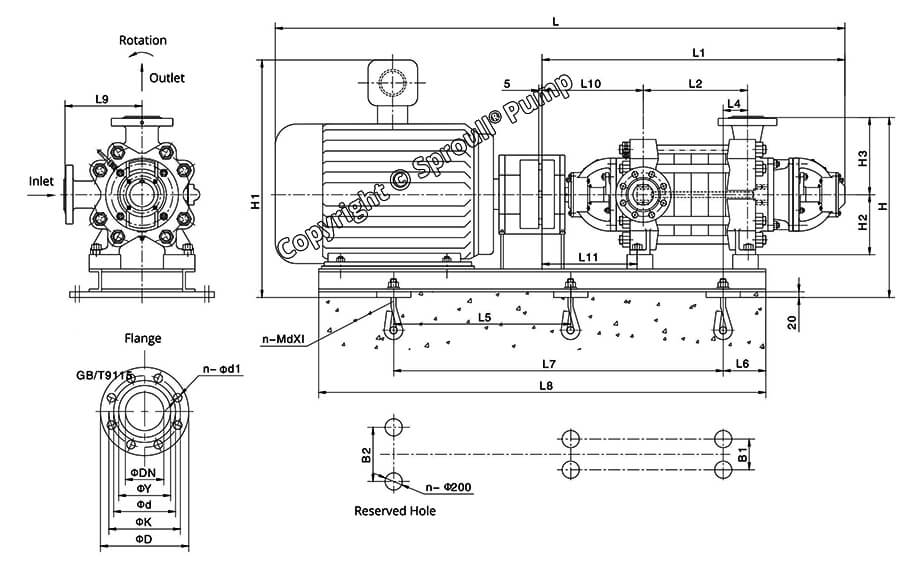

Sproull® SU Installation Drawing(Demonstration)

| Type | Motor | Installation Dimensions(mm) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | L1 | L2 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | L11 | H | H1 | H2 | H3 | B1 | B2 | n | Md×I | |||

| power(kw) | volt | ||||||||||||||||||||

| SU46-50×6 | 75 | 380 | 2136 | 1121 | 425 | 224 | 515 | 257 | 1030 | 1610 | 270 | 355 | 333 | 690 | 930 | 210 | 270 | 510 | 620 | 6 | M20×300 |

Capacity:35-580 m³/h

Head:270-2150 m

Speed:2950,1480 r/min

NPSHr:2.0-7.0m

Power:4-4500kw

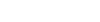

Design features:

• Horizontal,single-suction,multistage centrifugal pump design

• Stator- It consists of inlet, middle and outlet sections and the guide vane etc. with the take-up bolt tightly clamping all sections to form a working room. The inlet of it stands horizontally while the outlet vertically upward.

• Rotor – It consists of the shaft, impeller, balancing disk and shaft sleeve etc. The shaft passes the power to the impeller to have it work. The balancing disk balances the axial force, and replaceable shaft sleeve is mounted on both sides of the shaft to protect it.

• Bearings – There are rolling bearing and sliding bearing. The rolling bearing consists of bearing seat, bearing, bearing gland and using grease lubrication. The sliding bearing consists of bearing body, cover, liner, dust-proof disk, oil level, oil throwing ring etc. and using thin oil lubrication.

• Shaft seal – The shaft is sealed with packing and the shaft seal consists of the sealing contents, packing, baffle. the liquid in the sealing work-room fuctions water-sealing, water cooling and water lubricating and the water for water sealing comes from the pressure water inside of the pump, The mechanical seal also can be used as requested.

• Direction – The pump is directly driven by motor through the elastic pin coupling, and viewing from the motor, The pump is clockwise rotation.