ICF Corrosion Resistant Pump

ICF Corrosion Resistant Pump is a single-stage, single-suction Centrifugal pump, the improvement of ICJ pump, medium flow part of the material for F4, F46. With high temperature resistance, strong corrosion performance. Widely used in chemical, pharmaceutical, petroleum, metallurgy, smelting, power, electroplating, printing and dyeing, pesticides, paper, food, chemical fiber and other industries.

ICF Corrosion Resistant Pump can transport various acid-base strong oxidant and other corrosive media at -80 °C ~ +200 °C for a long time.

ICF Corrosion Resistant Pump can transport various acid-base strong oxidant and other corrosive media at -80 °C ~ +200 °C for a long time.

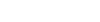

Structure Drawing of Type Sproull® ICF Pump

| 1 | choma | 5 | pump casing cover | 9 | front bearing cover | 13 | rear bearing | 17 | disc nut,retaining washer |

|---|---|---|---|---|---|---|---|---|---|

| 2 | pump casing | 6 | impeller“0”ring | 10 | mechanical seal | 14 | rear bearing cover | 18 |

suspension support bracket |

| 3 | closed impeller | 7 | fluid block loop | 11 | bearing housing | 15 | dust cover | ||

| 4 | pump casing cover seal washer | 8 | front bearing | 12 | circlips for hole | 16 | the packing gland |

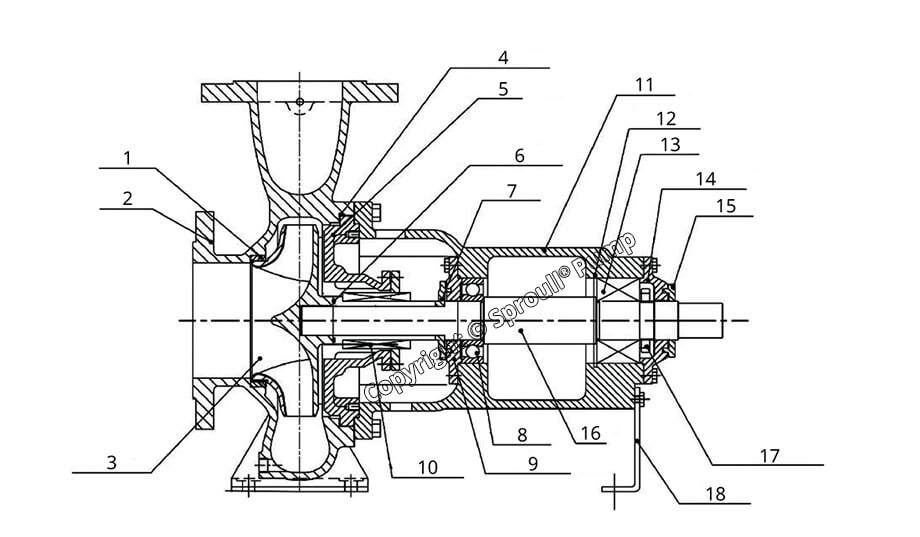

Sproull® ICF Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| ICF125-100-315 | |||

| ICF | GB standard single-stage single suction chemical industry pump | ||

| 125 | refer to pump suction diameter(mm) | ||

| 100 | refer to pump dischange diameter(mm) | ||

| 315 | refer to impeller nominal diameter(mm) | ||

Sproull® ICF Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Shaft power pa(kw) |

Motor power (kw) |

NPSHr (m) |

|---|---|---|---|---|---|---|---|

| 50-32-250 | 1450 | 6.3 | 20 | 27 | 1.27 | 2.2 | 1.2 |

| 65-40-250 | 1450 | 12.5 | 20 | 39 | 1.75 | 4 | 1.2 |

| 80-50-250 | 1450 | 25 | 20 | 52 | 2.62 | 5.5 | 1.4 |

| 100-65-250 | 1450 | 50 | 20 | 63 | 4.3 | 7.5 | 2.5 |

| 125-100-250 | 1450 | 100 | 20 | 72 | 7.56 | 11 | 2.3 |

| 150-125-400 | 1450 | 200 | 50 | 70 | 38.9 | 55 | 3.5 |

| 200-150-315 | 1450 | 400 | 32 | 79 | 44.1 | 75 | 3.5 |

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

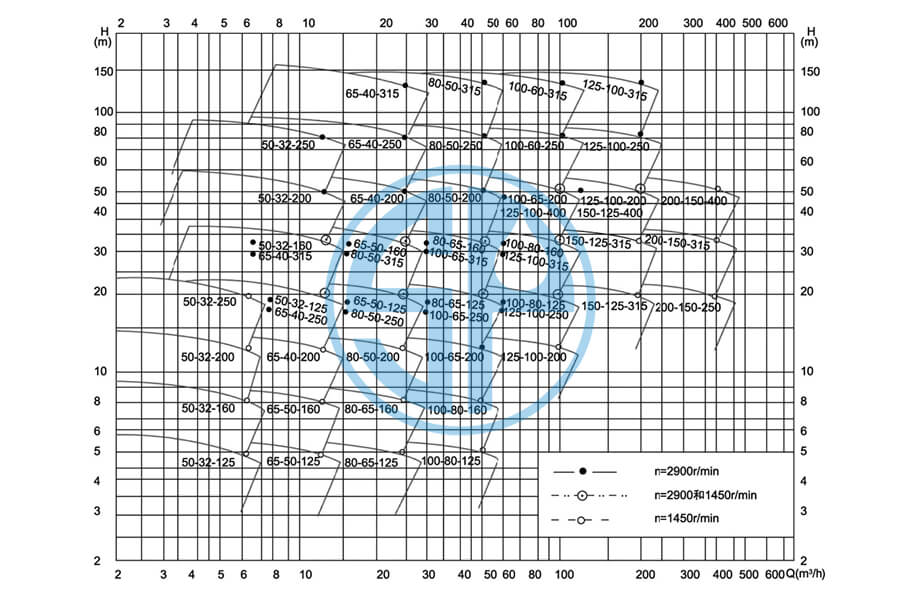

Sproull® ICF Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | H1 | H2 | H3 | Inlet flange | Outlet flange | |||||||||||||

| a1 | a2 | a3 | a4 | a5 | a6 | m-Φ1 | b1 | b2 | b3 | b4 | b5 | b6 | n-Φ1 | ||||||||||||

| ICF125-100-315 | 1380 | 100 | 590 | 590 | 80 | 140 | 550 | 610 | 705 | 250 | 390 | 250 | 210 | 184 | 125 | 22 | 3 | 8-Φ17.5 | 220 | 180 | 211 | 156 | 22 | 3 | 8-Φ17.5 |

Working Condition:

Capacity: 2-650 m³/h

Head: 3.5-150 m

Working pressure:<1.6Mpa

Materials:304,2507,316、316L、HastelloyC,B、C4、20*alloy、8*alloy CW-2、 Ceramicetc.

Design features:

Capacity: 2-650 m³/h

Head: 3.5-150 m

Working pressure:<1.6Mpa

Materials:304,2507,316、316L、HastelloyC,B、C4、20*alloy、8*alloy CW-2、 Ceramicetc.

Design features:

•The pump adopts a structure of rear-door, for facilitating maintenance without dismantling pipe system of inlet and outlet. Much convenience in application.

•The pump casing is designed with feet below, and discharge is positioned upward, suction in the axial.

•Use harassing coupling bolt, merely remove motor to disassembie hanging yoke part.