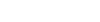

ICJ Chemical Centrifugal Pump

Spring® ICJ Chemical Centrifugal Pump is single-stage end-suction (axial suction) cantilever typecentrifugal pump, which is used to transport corrosive liquid with viscosity similar to water and without solid particles. The marked and rated performances and dimensions adopt IS02858 international standard,the manufacturing technical conditions are in accordance with ISO5199 and the structural design is in accordance with API610.

This series pump is a new improvement of h series pump. It adopts the mechanical seal and various technical measures to reduce the shaft diameter, so as to improve the whole pump performance.

Spring® ICJ Chemical Centrifugal Pump is applied to transport various corrosive media or media in which pollution is forbidden similar to water in such industries as chemical industry, petroleum, metallurgy, electric power, papermaking, food, pharmacy and synthetic fiber etc.

This series pump is a new improvement of h series pump. It adopts the mechanical seal and various technical measures to reduce the shaft diameter, so as to improve the whole pump performance.

Spring® ICJ Chemical Centrifugal Pump is applied to transport various corrosive media or media in which pollution is forbidden similar to water in such industries as chemical industry, petroleum, metallurgy, electric power, papermaking, food, pharmacy and synthetic fiber etc.

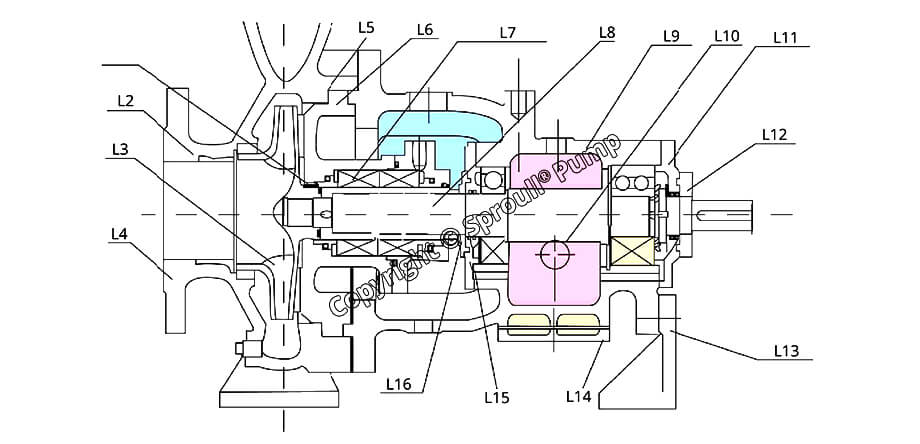

Structure Drawing of Type Sproull® ICJ Pump

| 1 | O-ring | 5 | Wearing ring | 9 | Bearing support | 13 | Suspension bracket |

|---|---|---|---|---|---|---|---|

| 2 | Wear-resistant rubber lining | 6 | Casing cover | 10 | Shaft cup | 14 | Water cooling jacket cover |

| 3 | Impeller | 7 | Cartridge mechanical seal | 11 | Rear bearing cap | 15 | Front bearing cap |

| 4 | Volute casing | 8 | Shaft | 12 | Dust cover | 16 | Baffle ring |

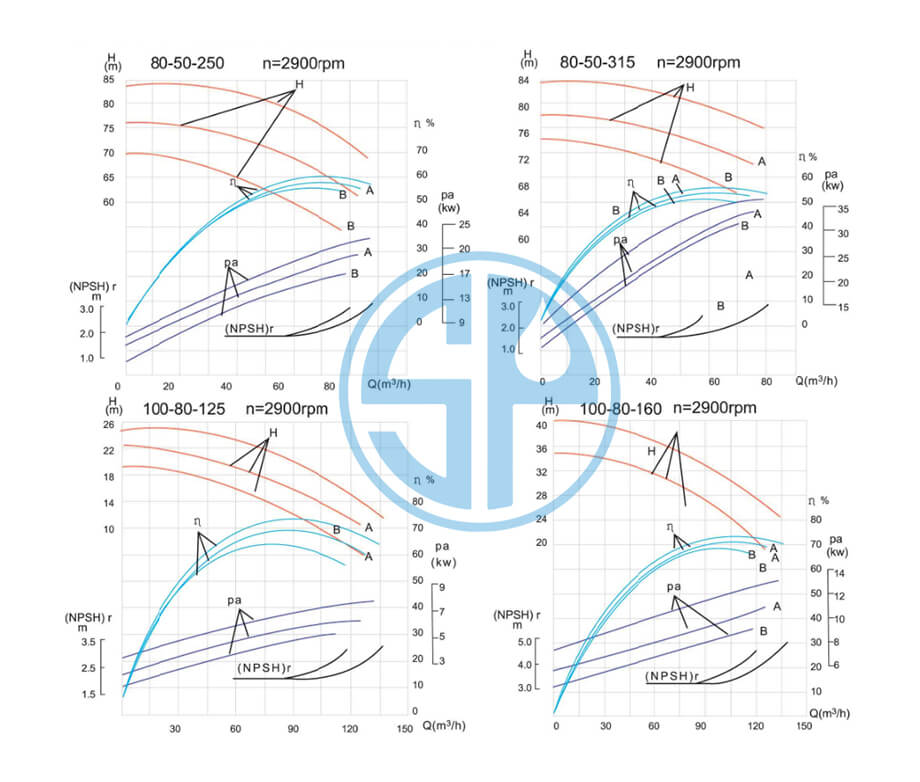

Sproull® ICJ Preformance Curve(Demonstration)

| lllustrations of Model Type | |||

|---|---|---|---|

| ICJ200-150-400 | |||

| ICJ | GB standard single-stage single suction chemical industry pump | ||

| 200 | refer to pump suction diameter(mm) | ||

| 150 | refer to pump dischange diameter(mm) | ||

| 400 | refer to impeller nominal diameter(mm) | ||

Sproull® ICJ Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Shaft power pa(kw) |

Motor power (kw) |

NPSHr (m) |

|---|---|---|---|---|---|---|---|

| 50-32-250 | 1450 | 6.3 | 20 | 27 | 1.27 | 2.2 | 1.2 |

| 50-32-250 | 2900 | 12.5 | 80 | 33 | 8.25 | 15 | 2.0 |

| 65-40-250 | 1450 | 12.5 | 20 | 39 | 1.75 | 4 | 1.2 |

| 65-40-250 | 2900 | 23.3 | 69 | 46 | 9.52 | 15 | 2.5 |

| 80-50-250 | 1450 | 25 | 20 | 52 | 2.62 | 5.5 | 1.4 |

| 80-50-200 | 2900 | 50 | 50 | 63 | 10.8 | 15 | 2.5 |

| 100-65-250 | 1450 | 50 | 20 | 63 | 4.3 | 7.5 | 2.5 |

| 100-65-200 | 2900 | 100 | 50 | 72 | 18.9 | 30 | 3.9 |

| 125-100-250 | 1450 | 100 | 20 | 72 | 7.56 | 11 | 2.3 |

| 125-100-315 | 2900 | 200 | 125 | 70 | 97.2 | 160 | 5.2 |

| 150-125-400 | 1450 | 200 | 50 | 70 | 38.9 | 55 | 3.5 |

| 200-150-400 | 1450 | 400 | 50 | 78 | 69.8 | 90 | 3.5 |

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

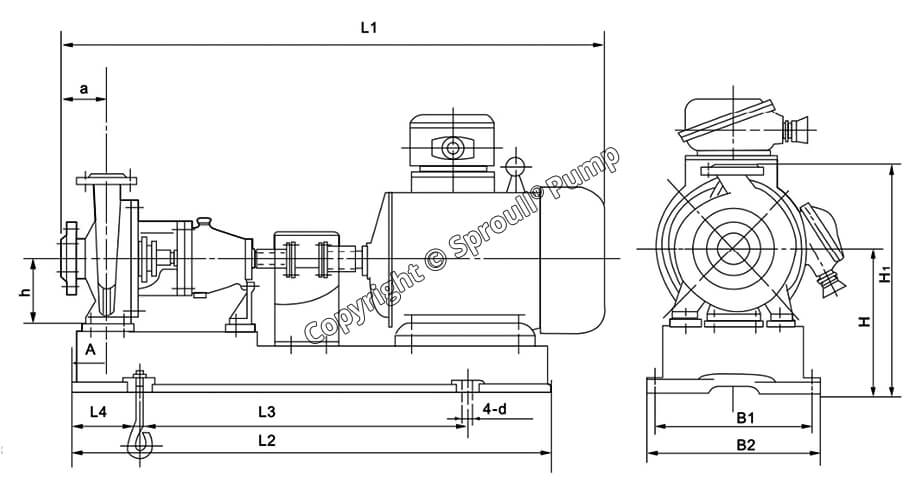

Sproull® ICJ Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | A | L1 | L2 | L3 | L4 | B1 | B2 | 4-Φd | h | H | H1 | |

| ICJ200-150-400 | 160 | 110 | 2260 | 1800 | 1200 | 300 | 670 | 730 | 4-Φ26 | 315 | 465 | 915 |

Working Condition:

Capacity: 2-650 m³/h

Head: 3.5-150 m

Working pressure:<1.6Mpa

Working Temperature:-50℃- +200℃

Materials:316、316L、HastelloyC,B、C4、20*alloy、8#alloy CW-2 etc.

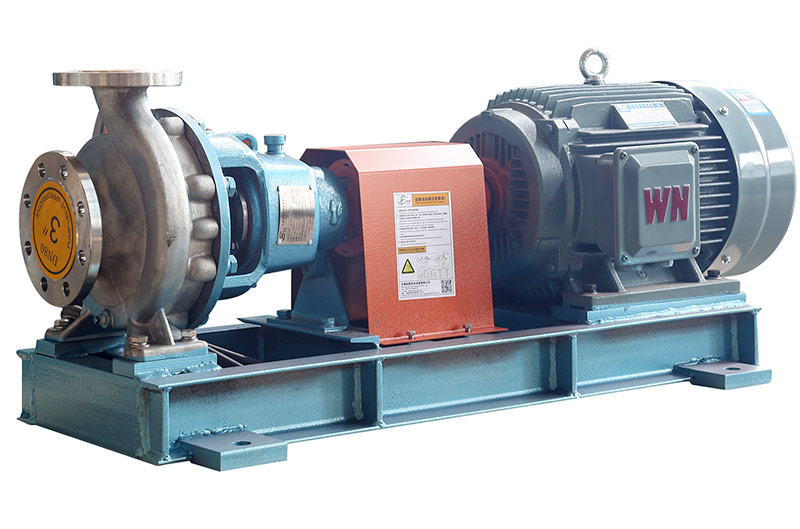

Design features:

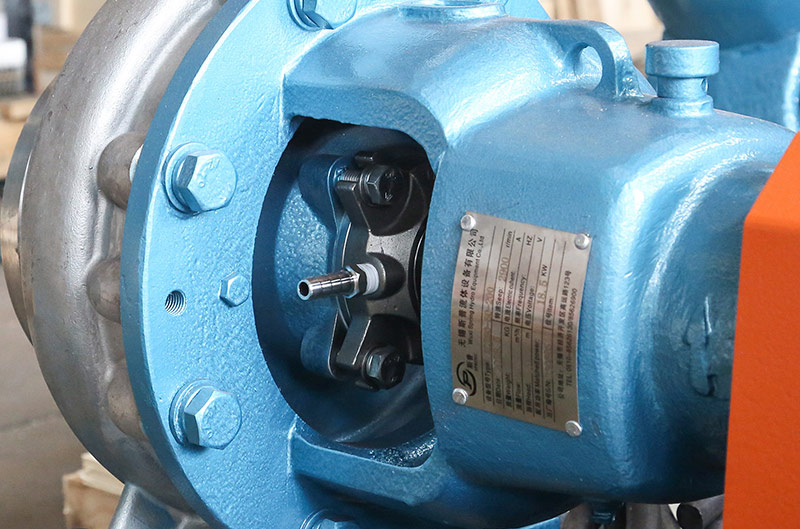

•Compare with the IH pump,Large cone-angle cavity of axle seal box. The machine seal is placed in a spacious cavity.

•The Container Type double-faced mechanical seal effectively realizes the forced circulation cooling in the mechanical seal.

•The enlarged shaft diameter reduces the deflection of the rotor and makes the operation stable.

•Simple structure, easy maintenance.

Capacity: 2-650 m³/h

Head: 3.5-150 m

Working pressure:<1.6Mpa

Working Temperature:-50℃- +200℃

Materials:316、316L、HastelloyC,B、C4、20*alloy、8#alloy CW-2 etc.

Design features:

•Compare with the IH pump,Large cone-angle cavity of axle seal box. The machine seal is placed in a spacious cavity.

•The Container Type double-faced mechanical seal effectively realizes the forced circulation cooling in the mechanical seal.

•The enlarged shaft diameter reduces the deflection of the rotor and makes the operation stable.

•Simple structure, easy maintenance.