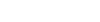

LYK Long Shaft Submerged Pump

Spring® LYK Long Shaft Submerged Pump is single stage and single suction with radial split long shaft submerged pumps. The pumps are suitable for handling clean liquid without solids, or sewage water with solids, slurry and corrosive liquid.

Spring® LYK Long Shaft Submerged Pump is mainly applied for industries like sewage treatment, power plant, steel-making plant, oil refineries, petro chemicals, coal industries etc.

Spring® LYK Long Shaft Submerged Pump is mainly applied for industries like sewage treatment, power plant, steel-making plant, oil refineries, petro chemicals, coal industries etc.

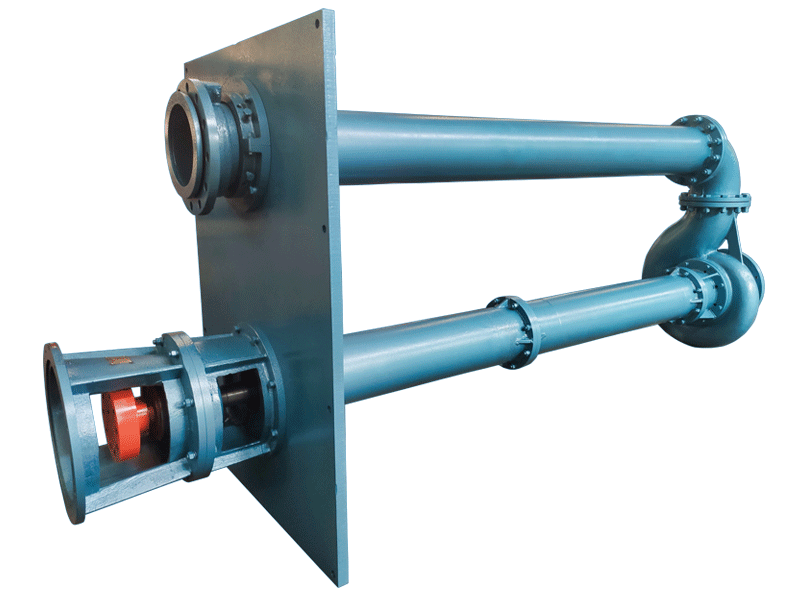

Structure Drawing of Type Sproull® LYK Pump

| 1 | Volute casing | 5 | Sealing seal | 9 | Middle support tube | 13 | Bracket | 17 | Oil water pipe |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Impeller | 6 | Lower shaft | 10 | Middle bearing support | 14 | Electric motor | ||

| 3 | Casing cover | 7 | Lower support tube | 11 | Upper support tube | 15 | Upper shaft | ||

| 4 | Machine seal cover | 8 | Lower bearing support | 12 | Support plate | 16 | Discharge pipe |

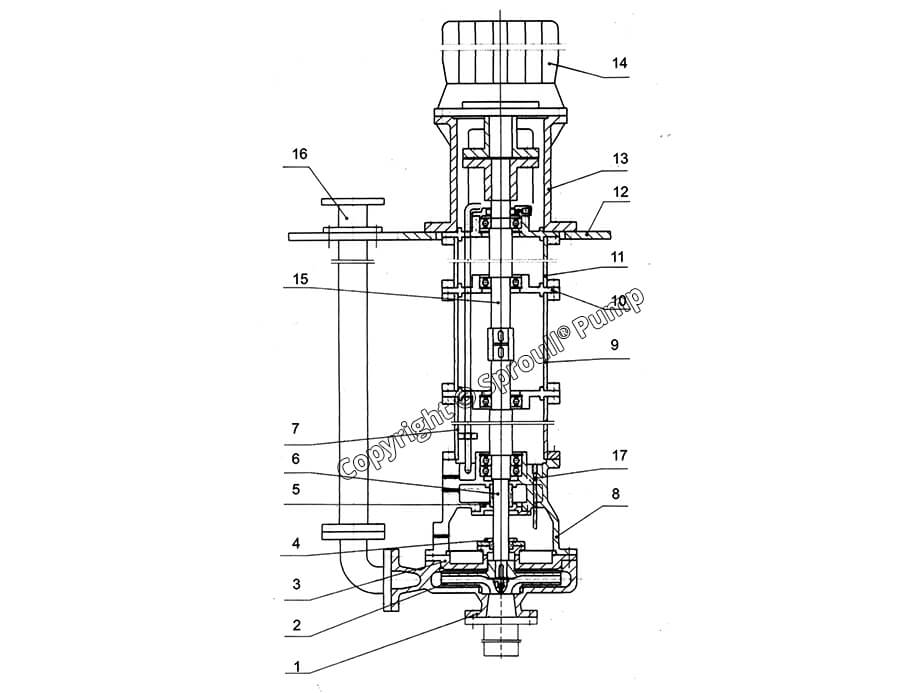

Sproull® LYK Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| LYK150-400 | |||

| LYK | Vertical Long Shaft Submerged Pump | ||

| 150 | Outlet Diameter(mm) | ||

| 400 | Impeller diameter(mm) | ||

Sproull® LYK Preformance parameter list

| Type |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Motor power kw |

|---|---|---|---|---|---|---|---|---|

| LYK32-250 | 1450 | 8 | 11 | 2.2 | 2900 | 15 | 50 | 7.5 |

| 9 | 15 | 2.2 | 18 | 65 | 11 | |||

| 11 | 20 | 2.2 | 20 | 85 | 15 | |||

| LYK40-160 | 1450 | 12 | 4 | 1.1 | 2900 | 14 | 18 | 3 |

| 14 | 6 | 1.1 | 16 | 26 | 5.5 | |||

| 15 | 8 | 1.1 | 30 | 34 | 7.5 | |||

| LYK50-160 | 1450 | 20 | 4 | 1.1 | 2900 | 40 | 18 | 5.5 |

| 24 | 6 | 1.1 | 46 | 26 | 5.5 | |||

| 30 | 8 | 1.5 | 55 | 34 | 11 | |||

| LYK65-200 | 1450 | 36 | 7 | 2.2 | 2900 | 70 | 30 | 11 |

| 42 | 10 | 3 | 90 | 40 | 18.5 | |||

| 50 | 13 | 4 | 100 | 54 | 22 | |||

| LYK80-250 | 1450 | 70 | 11 | 5.5 | 2900 | 130 | 47 | 30 |

| 85 | 17 | 5.5 | 170 | 70 | 45 | |||

| 90 | 20 | 11 | 180 | 75 | 55 | |||

| LYK80-315 | 1450 | 70 | 18 | 15 | 2900 | 150 | 75 | 55 |

| 85 | 24 | 15 | 160 | 100 | 75 | |||

| 100 | 32 | 15 | 200 | 130 | 110 | |||

| LYK100-250 | 1450 | 100 | 10 | 11 | 2900 | 200 | 40 | 37 |

| 120 | 14 | 11 | 230 | 55 | 55 | |||

| 130 | 20 | 15 | 280 | 75 | 90 | |||

| LYK100-315 | 1450 | 90 | 21 | 15 | 2900 | 200 | 85 | 75 |

| 100 | 26 | 15 | 230 | 100 | 110 | |||

| 132 | 32 | 30 | 270 | 135 | 160 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

||||||||

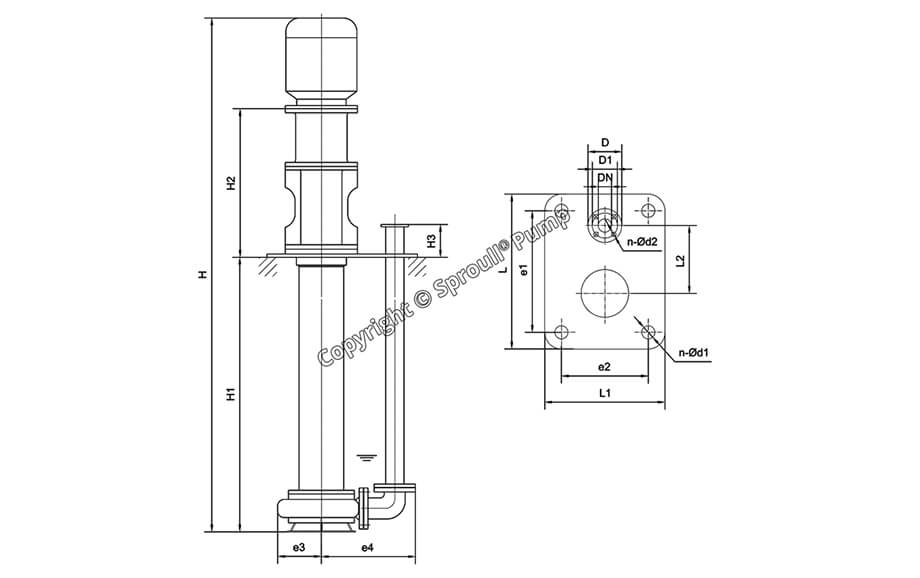

Sproull® LYK Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | H3 | L | L1 | L2 | e1 | e2 | e3 | e4 | D | D1 | DN | n-Φd1 | n-Φd2 | |

| LYK80-38 | 2300 | 810 | 136 | 900 | 700 | 505 | 820 | 620 | 233 | 610 | Φ200 | Φ160 | Φ80 | 4-Φ19 | 4-Φ18 |

Working Condition:

Capacity: 2~400m³/h

Head: 5-200m

Operating pressures:<2.5MPa

Working Temperature:-20℃~+120℃

Materials: HT200, QT600, 304, 304L, 316L, 317L, 904L,CD4.

Design features:

•The pump casing is radial split, and is double volute casing design for flange nominal size 80mm and above so as to reduce radial force and pump vibration caused by hydraulic acting.

•The impellor and diffuser are multi-stage design which can meet various requirement in head.

•The axial force is balanced through balancing hole for impellor.

•The Pump shaft is designed for reliable extension-connection type with multi-supporting point, which guaranteed stable operation under critical services. The maximum submergence length is 10m.

•The pump shaft can be protected by tube to avoid wearing or corrosion. And the protection tube is unnecessary when clean water is handled.

•Separate discharge pipe of pump has no pressurized liquid leakage in shaft direction. And if used in open type of system, the shaft seal is no necessary; If used in close type of system as well as easy volatile or toxic liquid, mechanical seal or packing seal will be available.

Capacity: 2~400m³/h

Head: 5-200m

Operating pressures:<2.5MPa

Working Temperature:-20℃~+120℃

Materials: HT200, QT600, 304, 304L, 316L, 317L, 904L,CD4.

Design features:

•The pump casing is radial split, and is double volute casing design for flange nominal size 80mm and above so as to reduce radial force and pump vibration caused by hydraulic acting.

•The impellor and diffuser are multi-stage design which can meet various requirement in head.

•The axial force is balanced through balancing hole for impellor.

•The Pump shaft is designed for reliable extension-connection type with multi-supporting point, which guaranteed stable operation under critical services. The maximum submergence length is 10m.

•The pump shaft can be protected by tube to avoid wearing or corrosion. And the protection tube is unnecessary when clean water is handled.

•Separate discharge pipe of pump has no pressurized liquid leakage in shaft direction. And if used in open type of system, the shaft seal is no necessary; If used in close type of system as well as easy volatile or toxic liquid, mechanical seal or packing seal will be available.