LYD Light Submerged Pump

Spring® LYD Light Submerged Pump is a vertical single-stage single-suction cantilever centrifugal pump structure, impeller is a semi-open impeller, in the impeller suction side extension with stirring blades, to facilitate the transportation of large particles viscous liquid.

Spring® LYD Light Submerged Pump is specially used in aerated concrete projects and various working conditions where the conveying medium needs to be mixed,also can be used for chemical, pharmaceutical and other industries containing mud and sand sludge fluid and corrosive liquid.

Spring® LYD Light Submerged Pump is specially used in aerated concrete projects and various working conditions where the conveying medium needs to be mixed,also can be used for chemical, pharmaceutical and other industries containing mud and sand sludge fluid and corrosive liquid.

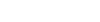

Structure Drawing of Type Sproull® LYD Pump

| 1 | Motor | 5 | Mounting plate | 9 | Main shaft | 13 | Mechanical seal | 17 | Volute casing |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Motor stand | 6 | Highest starting liquid level | 10 | Connecting seat | 14 | Lowest starting liquid level | 18 | Lowest stopping liquid level |

| 3 | Coupling | 7 | Scoop pipe | 11 | Bearing at pump end | 15 | Pump cover | 19 | Suck in barrel |

| 4 | Upper bearing | 8 | Connecting stand | 12 | Bearing gland | 16 | Impeller |

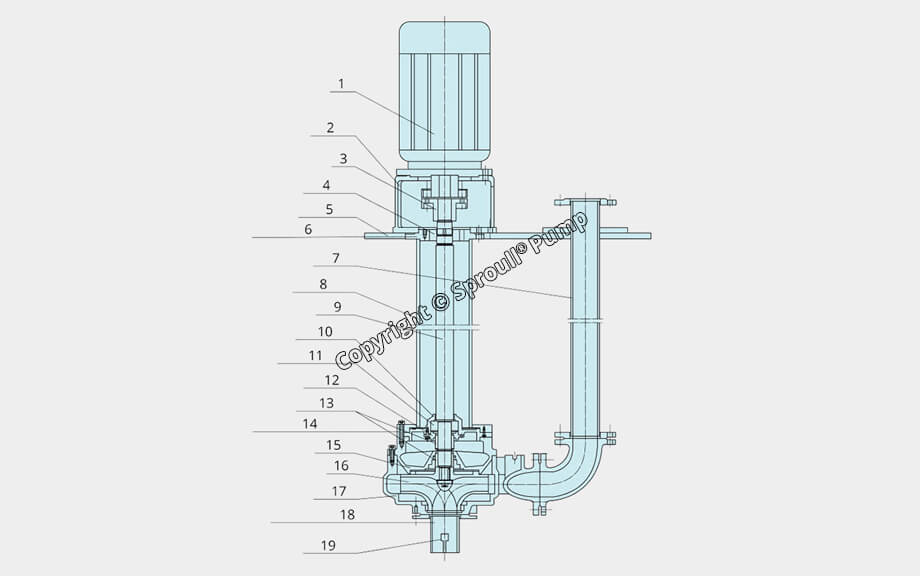

Sproull® LYD Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| 50LYD-250 | |||

| 50 | Outlet diameter is 50mm | ||

| LYD | Vertical slurry pump | ||

| 250 | Impeller nominal diameter is 250mm | ||

Sproull® LYD Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Motor power (kw) |

|---|---|---|---|---|---|

| 50LYD-28 | 940 | 10.2 | 12.5 | 41 | 2.2 |

| 13.6 | 11.6 | 42 | |||

| 17 | 11 | 45 | |||

| 65LYD-28 | 1460 | 28 | 29 | 41 | 15 |

| 37 | 27 | 42 | |||

| 46 | 26 | 45 | |||

| 80LYD-38 | 980 | 33 | 22.8 | 35 | 22 |

| 43 | 21.9 | 44 | |||

| 49.6 | 21 | 48 | |||

| 80LYD-36 | 1480 | 86 | 47.1 | 47.4 | 30 |

| 151 | 42 | 60.7 | |||

| 167 | 39.9 | 62 | |||

| 100LYD-36 | 980 | 63.6 | 19.7 | 43.8 | 30 |

| 106 | 17.1 | 52 | |||

| 127 | 15.8 | 50.6 | |||

| 150LYD-40 | 730 | 125 | 11.7 | 47 | 30 |

| 208.6 | 11.1 | 62 | |||

| 250.3 | 9.2 | 57 | |||

| 200LYD-34 | 1480 | 276 | 38 | 59 | 90 |

| 460 | 35 | 69 | |||

| 552 | 33 | 64 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||

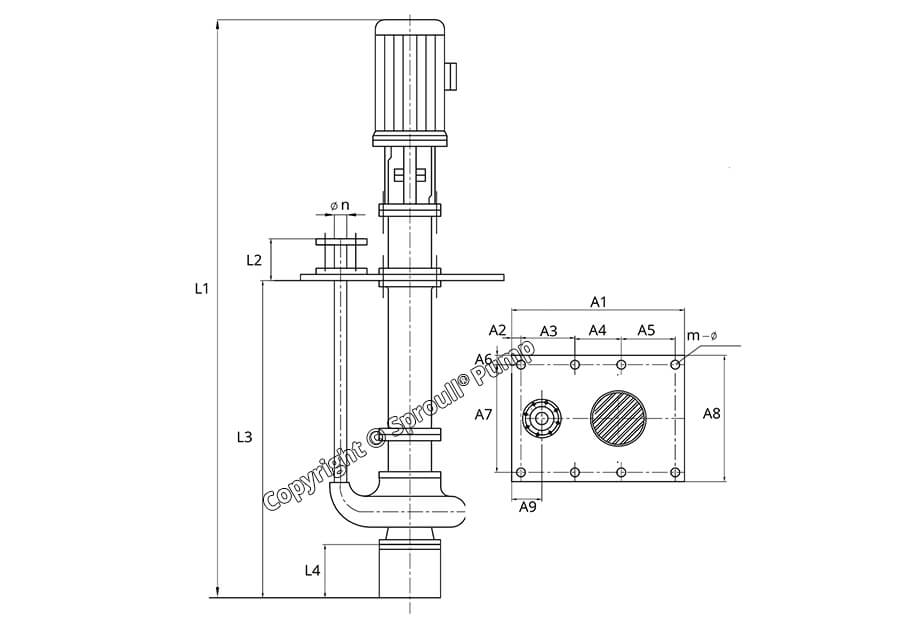

Sproull® LYD Installation Drawing(Demonstration)

| Type | Motor | Installation Dimensions(mm) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | Φn | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A9 | m-Φ1 | outlet flange | ||

| power(kw) | |||||||||||||||||

| LYD150-400 | 37 | 4030 | 225 | 2500 | 500 | Φ150 | 1525 | 42.5 | 480 | 480 | 480 | 470 | 870 | 960 | 370 | 8-Φ26 | DN150(PN2.5MPa) |

Working Condition:

Capacity: 10~550 m³/h

Head: 11-65 m

Speed:730~1480 r/min

Materials: Ceramics, HT200, QT600, 304, 304L, 316L, 317L, 904L,CD4.

Design features:

Capacity: 10~550 m³/h

Head: 11-65 m

Speed:730~1480 r/min

Materials: Ceramics, HT200, QT600, 304, 304L, 316L, 317L, 904L,CD4.

Design features:

•Mixing Blade design, to meet the conditions of easy settlement or, concentration, viscosity greater conditions.

•Using high strength bearing, anti-disturbance, anti-distortion, strong load-bearing capacity, smooth operation.

•Adopt no shaft seal design, reasonable structure, easy to maintain.

•The flow parts are made of all-metal anti-wear white cast iron (CR27), which has good anti-wear property.

•Bearing Grease Lubrication, according to the technical requirements of regular injection grease, can greatly extend the service life of bearing components.