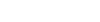

ZD Self-priming Sewage Pump is applicable to urban environmental protection, construction, fire protection, chemical industry, pharmacy, dye,printing and dyeing, brewing, electric power, ferry, paper making,industrial and mining washing, equipment cooling, etc.

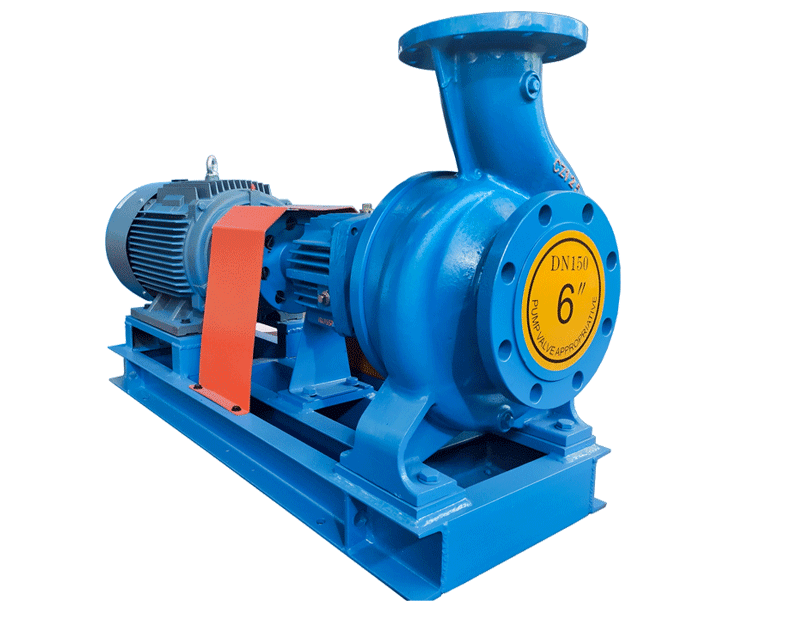

Structure Drawing of Type Sproull® ZD Pump

| 1 | Coupling components | 7 | Bearing seat | 13 | Self-priming pump body | 19 | Self-priming pump cover | 25 | Front bearing |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Coupling key | 8 | Stoma cover | 14 | Self-priming impeller | 20 | O-ring | 26 | Oil mark |

| 3 | Dust Cover | 9 | Circlip | 15 | PTFE mat | 21 | Impeller key | 27 | Rear bearing gland |

| 4 | Small Round Nut | 10 | Axles | 16 | O-ring | 22 | Water pipe joint | 28 | Suspension bracket |

| 5 | Stop washer | 11 | Water pipe joint | 17 | Pump body | 23 | Front bearing gland | ||

| 6 | Rear bearing | 12 | Mechanical Seal | 18 | Impeller | 24 | Baffle ring |

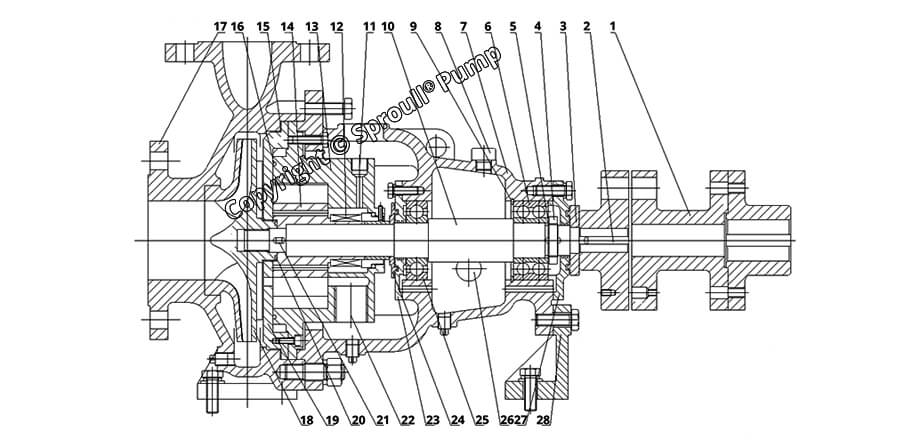

Sproull® ZD Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| ZD80-50-200 | |||

| ZD | Self-priming Centrifugal pump | ||

| 80 | Refer to pump suction diameter(mm) | ||

| 50 | Refer to pump dischange diameter(mm) | ||

| 200 | Refer to impeller nominal diameter(mm) | ||

Sproull® ZD Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Shaft power pa(kw) |

Motor power (kw) |

NPSHr (m) |

|---|---|---|---|---|---|---|---|

| 50-32-250 | 2900 | 12.5 | 80 | 33 | 8.25 | 15 | 2.0 |

| 65-40-250 | 2900 | 23.3 | 69 | 46 | 9.52 | 15 | 2.5 |

| 80-50-200 | 2900 | 50 | 50 | 63 | 10.8 | 15 | 2.5 |

| 100-65-200 | 2900 | 100 | 50 | 72 | 18.9 | 30 | 3.9 |

| 125-100-315 | 2900 | 200 | 125 | 70 | 97.2 | 160 | 5.2 |

| 150-125-400 | 1450 | 200 | 50 | 70 | 38.9 | 55 | 3.5 |

| 200-150-400 | 1450 | 400 | 50 | 78 | 69.8 | 90 | 3.5 |

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

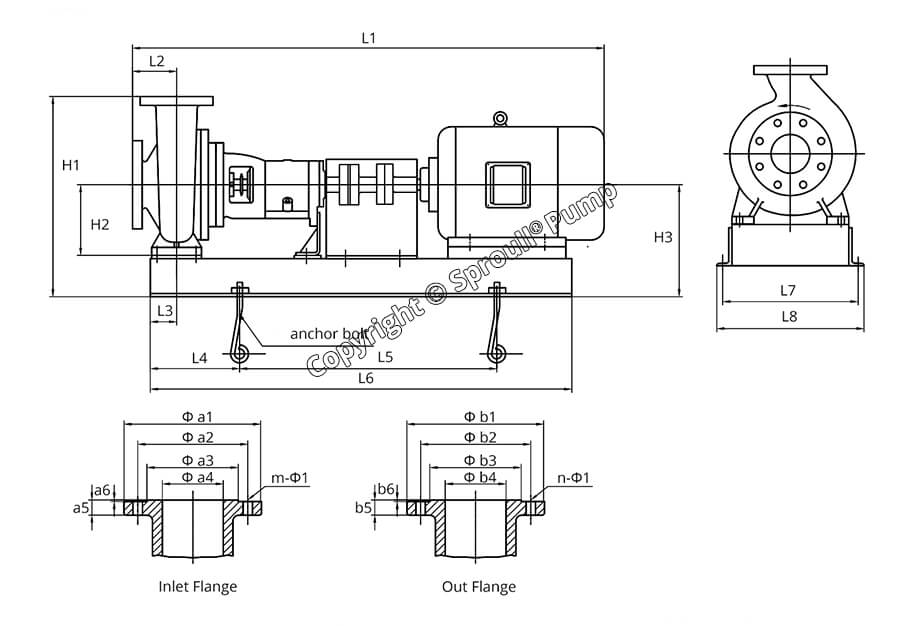

Sproull® ZD Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | H1 | H2 | H3 | Inlet flange | Outlet flange | |||||||||||||

| a1 | a2 | a3 | a4 | a5 | a6 | m-Φ1 | b1 | b2 | b3 | b4 | b5 | b6 | n-Φ1 | ||||||||||||

| ZD80-50-200 | 1185 | 100 | 60 | 100 | 820 | 1020 | 445 | 505 | 476 | 160 | 276 | 200 | 160 | 132 | 80 | 20 | 3 | 8-Φ17.5 | 165 | 125 | 99 | 50 | 20 | 3 | 4-Φ17.5 |

Capacity: 2-650m³/h

Head: 3.5-150m

Working pressure:<1.6Mpa

Working Temperature:-50 – +200℃

Materials:304,316L,2507 Stainless steel,Steel Lining Teflon.

Design features:

• The pump is with self-priming performance, It don’t need any bottom valve.

• Electric motor and diesel engine driven for options.

• The total weight of impurities in the medium can not exceed 15% of the total media weight.

• Medium specific weight not more than 1240kg/m³.

• The unique structure of open impeller makes sure the free pass of solids in sewage with max size of 60% of outlet DN and fiber 150% of impeller diameter.

• The self priming sewage pump is widely applicable for the lines of urban diacharge projects, light industry, papermaking, textile, foodstuff, chemicals, electric power, petroleum, mines, aquiculture and so on.