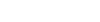

ISGB Portable type Pipeline Pump

Spring® ISGB Portable type Pipeline Pump is a single-stage single-suction vertical pipeline centrifugal pump,based on the ISG type, suitable hot water, high temperature, corrosive chemical pumps and oil pumps are dispatched according to the use temperature and medium. This series of products have the advantages of high efficiency, energy saving, low noise and reliable performance.

Spring® ISGB Portable type Pipeline Pump is used to transport liquids that do not contain solid particles, are corrosive, and have a viscosity in water. They are suitable for petroleum, chemical, metallurgical, electric power, paper, food and pharmaceutical and synthetic fiber sectors. The operating temperature is -20 ℃~120℃.

Spring® ISGB Portable type Pipeline Pump is used to transport liquids that do not contain solid particles, are corrosive, and have a viscosity in water. They are suitable for petroleum, chemical, metallurgical, electric power, paper, food and pharmaceutical and synthetic fiber sectors. The operating temperature is -20 ℃~120℃.

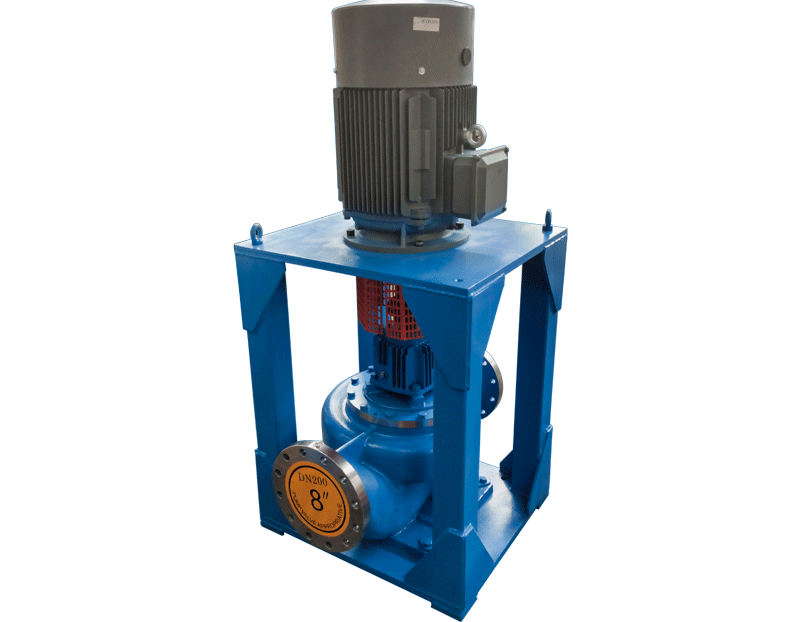

Structure Drawing of Type Sproull® ISGB Pump

| 1 | Casing | 5 | Release valve | 9 | Bracket | 13 | Pump coupling |

|---|---|---|---|---|---|---|---|

| 2 | Drain plug | 6 | Bearing housing | 10 | Motor | 14 | Oil Cup |

| 3 | Impeller | 7 | Bearing | 11 | Motor coupling | 15 | Bearing cover |

| 4 | Mechanical seal | 8 | Pump shaft | 12 | Intermediate coupling | 16 | Casing cover |

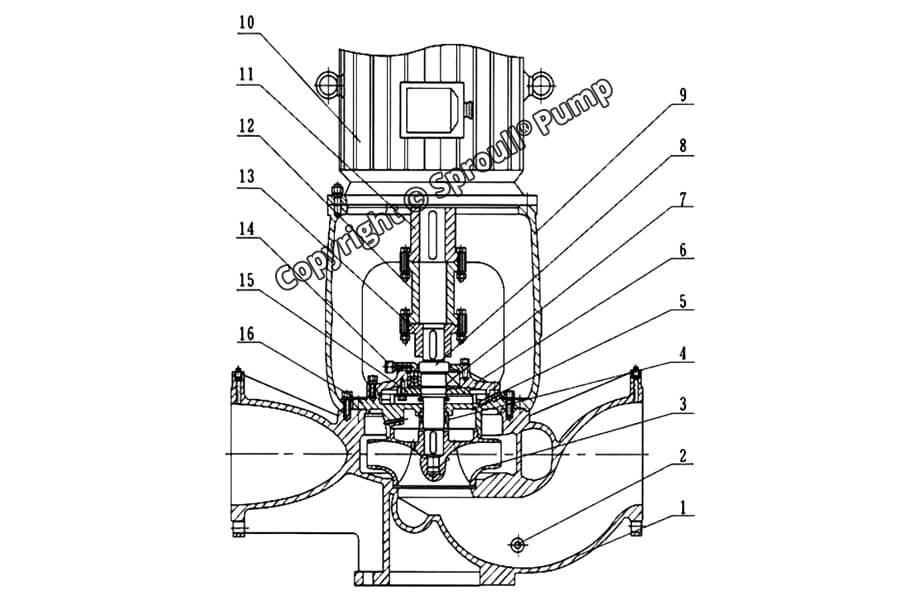

Sproull® ISGB Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| ISGB125-125 | |||

| ISGB | Single-stage single-suction pipeline chemical pump | ||

| 125 | Outlet Diameter(mm) | ||

| 125 | Impeller Diameter(mm) | ||

Sproull® ISGB Preformance parameter list

| Type |

speed n(r/min) |

capacity Q(m³/h) |

head H(m) |

Eff η(%) |

Motor power kw |

Max.disoontinuous solid particle |

|---|---|---|---|---|---|---|

| ISGB125-125 | 2900 | 96 | 22.6 | 80 | 15 | 4 |

| 160 | 20 | 80 | ||||

| 192 | 17 | 80 | ||||

| ISG200-250 | 1450 | 140 | 21.8 | 73 | 18.5 | 3 |

| 200 | 20 | 79 | ||||

| 260 | 17 | 77 | ||||

| ISGB250-400 | 1480 | 300 | 54.5 | 72 | 90 | 4.5 |

| 500 | 50 | 72 | ||||

| 600 | 39 | 72 | ||||

| ISGB300-480 | 980 | 540 | 31 | 79 | 75 | 5 |

| 720 | 28 | 81 | ||||

| 900 | 24 | 80 | ||||

| ISGB350-235 | 1480 | 600 | 14 | 80 | 37 | 4.5 |

| 800 | 12.5 | 83 | ||||

| 960 | 10.5 | 82 | ||||

| ISGB400-315 | 1480 | 820 | 36.5 | 76 | 132 | 6 |

| 1080 | 32 | 76 | ||||

| 1300 | 27 | 76 | ||||

| ISGB500-315 | 1480 | 1000 | 34.5 | 78 | 160 | 6 |

| 1200 | 32 | 78 | ||||

| 1450 | 27 | 78 | ||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

||||||

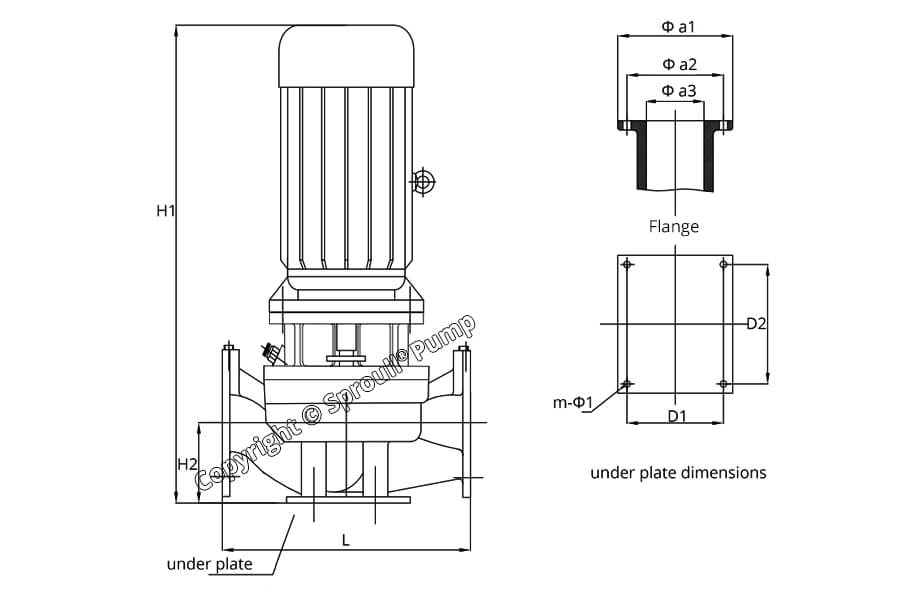

Sproull® ISGB Installation Drawing(Demonstration)

| Type | contour dimension(mm) | under plate dimension | flange | ||||||

|---|---|---|---|---|---|---|---|---|---|

| L | H1 | H2 | D1 | D2 | n-Φ1 | Φ a1 | Φ a2 | Φ a3 | |

| ISGB125-125 | 520 | 840 | 170 | 160 | 220 | 4-Φ18 | 250 | 210 | 125 |

Working Condition:

Suction pressure≤1.0Mpa(Maximum working pressure≤1.6MPa)

The Ambient temperature <40℃,the Relative humidity <40%.

The volume content of solid particles in the conveyed medium does not exceed 0.1 per unit volume, and the particle size is less than 0.2mm.

Design features:

Suction pressure≤1.0Mpa(Maximum working pressure≤1.6MPa)

The Ambient temperature <40℃,the Relative humidity <40%.

The volume content of solid particles in the conveyed medium does not exceed 0.1 per unit volume, and the particle size is less than 0.2mm.

Design features:

1.Vertical structure, easy to install and debug, unique design of motor and pump body using connection, high concentricity, high processing precision, greatly reduce the area, reduce the construction investment pump room 30%-60% . Firm footwork and compact construction.

2.The bearing uses the international famous brand precision bearing, the precision is high, the reliability is good, the service life is long.

3.Impeller with excellent self-balancing axial force hydraulic model, so that the pump bearing and mechanical seal service life is greatly extended.

4.Removable hard intermediate coupling, so that the pump starting without vibration, no noise, rotating parts with a reliable safety shield, safety is excellent.

5.The mechanical seal is made of stainless steel, tungsten carbide, fluorine rubber and other materials, high temperature, high pressure, long service life, no leakage, no wear on the shaft, to ensure a clean working environment.

6.The unique structure design of the pump cover, as long as the hard intermediate coupling, the pump cover nut, you can easily take out the bearing housing. Pump cover, pump shaft, impeller and other components, to replace the mechanical seal and Impeller, without the removal of motor, pump body and pipe, easy and quick maintenance.

2.The bearing uses the international famous brand precision bearing, the precision is high, the reliability is good, the service life is long.

3.Impeller with excellent self-balancing axial force hydraulic model, so that the pump bearing and mechanical seal service life is greatly extended.

4.Removable hard intermediate coupling, so that the pump starting without vibration, no noise, rotating parts with a reliable safety shield, safety is excellent.

5.The mechanical seal is made of stainless steel, tungsten carbide, fluorine rubber and other materials, high temperature, high pressure, long service life, no leakage, no wear on the shaft, to ensure a clean working environment.

6.The unique structure design of the pump cover, as long as the hard intermediate coupling, the pump cover nut, you can easily take out the bearing housing. Pump cover, pump shaft, impeller and other components, to replace the mechanical seal and Impeller, without the removal of motor, pump body and pipe, easy and quick maintenance.