OJS Single Stage Double Suction Centrifugal Pump

OJS Single Stage Double Suction Centrifugal Pump is single stage double suction horizontal split centrifugal clean water pump,it has high efficiency and energy saving character. With wide Performance range, superior hydraulic performance and reasonable structure, the series of pumps have high efficiency and reliability, low cavitations and cost for maintenance.

OJS Single Stage Double Suction Centrifugal Pump is mainly used for deliver fresh water or other liquids similar to fresh water, the solid content is not more than 80mg/L, it also can deliver sewage, sea water and muddy water with little particle with adopting of anti-corrosion and anti-friction material. The products are widely applicable to supply & drainage system or cooling & circulating system for iron & steel, petrochemical, thermo power plant and mines industries, etc. and running water system for cities, circulating water for heating system, irrigation projects and various water conservation projects, fire systems, shipbuilding industry as well.

OJS Single Stage Double Suction Centrifugal Pump is mainly used for deliver fresh water or other liquids similar to fresh water, the solid content is not more than 80mg/L, it also can deliver sewage, sea water and muddy water with little particle with adopting of anti-corrosion and anti-friction material. The products are widely applicable to supply & drainage system or cooling & circulating system for iron & steel, petrochemical, thermo power plant and mines industries, etc. and running water system for cities, circulating water for heating system, irrigation projects and various water conservation projects, fire systems, shipbuilding industry as well.

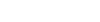

Structure Drawing of Type Sproull® OJS Pump :

| 1 | Pin | 7 | Packing | 13 | Impeller key | 19 | Lock nut | 25 | Bearing |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Bearing circlip | 8 | Water seal cage | 14 | Key | 20 | Water retaining ring | 26 | Bearing skeleton oil seal |

| 3 | Bearing | 9 | Packing sleeve | 15 | Stuffing box O-ring | 21 | Shaft | 27 | Coupling |

| 4 | Bearing washer | 10 | Wear ring | 16 | Skeleton oil seal | 22 | Wear ring fixing pin | 28 | Coupling key |

| 5 | Bearing gland | 11 | Impeller | 17 | Bearing | 23 | Sleeve O-ring | 29 | Coupling |

| 6 | Packing gland | 12 | Volute | 18 | Spring | 24 | Shaft O-ring |

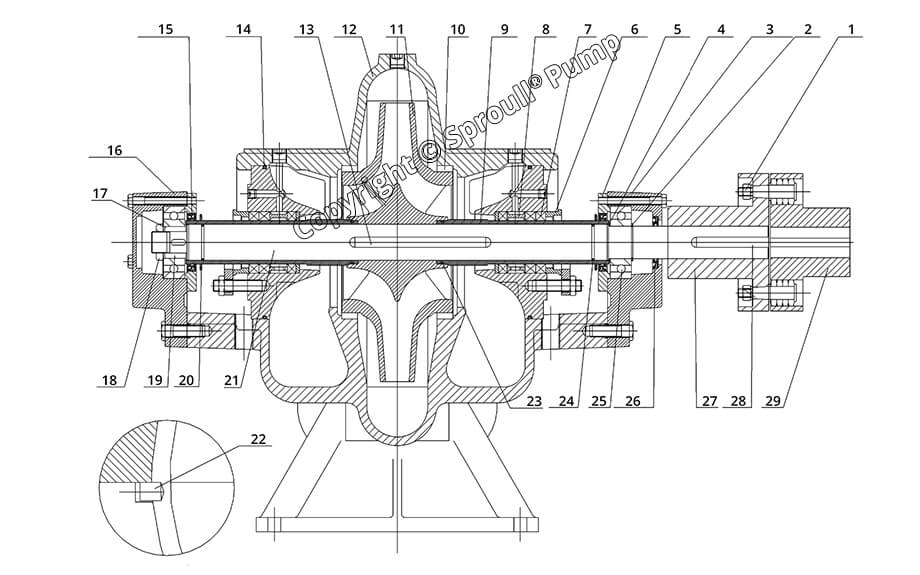

Sproull® OJS Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| OJS150-460 | |||

| OJS | Single Stage Double Suction Centrifugal Pump | ||

| 150 | Outlet Diameter(mm) | ||

| 460 | impeller Diameter(mm) | ||

Sproull® OJS Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Shaft power pa(kw) |

Impeller Dia. (mm) |

NPSH r(m) |

|---|---|---|---|---|---|---|---|

| OJS100-310 | 1450 | 148 | 34 | 78.5 | 17.4 | 325 | 3.1 |

| 185 | 31 | 80 | 19.6 | 325 | |||

| 222 | 26.8 | 77.2 | 21 | 325 | |||

| OJS125-230 | 1450 | 220 | 17 | 84 | 12.1 | 245 | 2.3 |

| 274 | 14.8 | 85.5 | 12.9 | 245 | |||

| 328 | 12 | 82 | 13.1 | 245 | |||

| OJS150-360 | 1450 | 357 | 41.3 | 83 | 48.4 | 355 | 3 |

| 446 | 38 | 85 | 54.3 | 355 | |||

| 536 | 34.2 | 82.7 | 60.4 | 355 | |||

| OJS200-670 | 1450 | 634 | 157.5 | 77.7 | 350 | 655 | 3.6 |

| 792 | 150 | 80 | 404 | 655 | |||

| 936 | 140 | 78.2 | 457 | 655 | |||

| OJS250-600 | 1450 | 994 | 126 | 83 | 411 | 610 | 4.6 |

| 1242 | 116 | 84 | 467 | 610 | |||

| 1490 | 105 | 82 | 520 | 610 | |||

| OJS300-700 | 1450 | 1469 | 170 | 84 | 810 | 705 | 4.95 |

| 1836 | 160 | 86 | 941 | 705 | |||

| 2070 | 151 | 84.2 | 1012 | 705 | |||

| OJS350-510 | 1450 | 2088 | 8 | 86 | 529 | 518 | 10 |

| 2610 | 70 | 88.5 | 562 | 518 | |||

| 3132 | 60 | 84.7 | 605 | 518 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

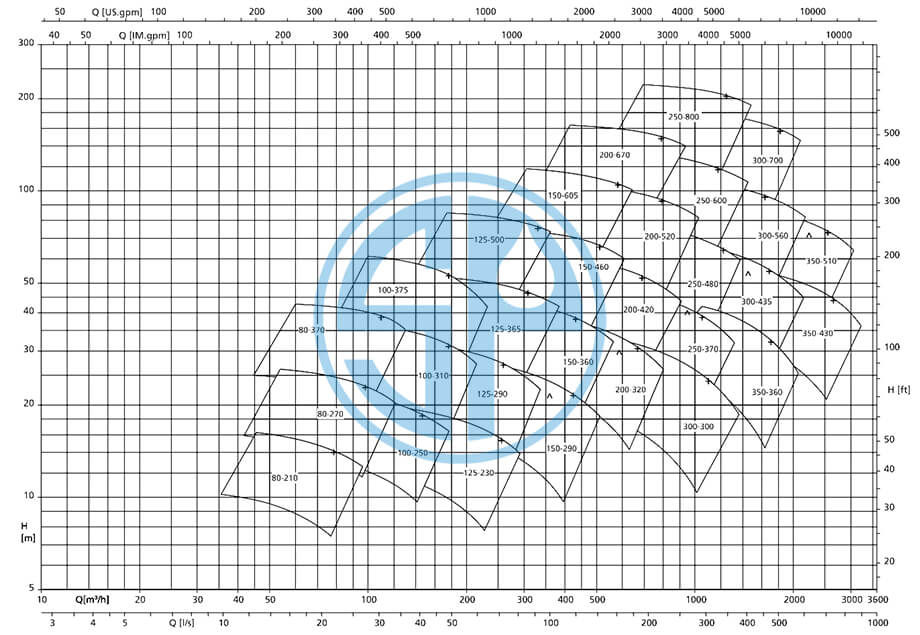

Sproull® OJS Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 | L10 | Inlet flange | Outlet flange | |||||||||

| a1 | a2 | a3 | a4 | m-Φ1 | b1 | b2 | b3 | b4 | n-Φ1 | |||||||||||

| OJS150-460 | 1900 | 399 | 590 | 5 | 100 | 100 | 650 | 650 | 1500 | 400 | 340 | 295 | 200 | 24 | 12-Φ22 | 285 | 240 | 150 | 24 | 8-Φ22 |

| L11 | L12 | L13 | H1 | H2 | H3 | H4 | H5 | H6 | z-Φ1 | |||||||||||

| 400 | 780 | 855 | 861 | 400 | 250 | 556 | 200 | 200 | 6-Φ16 | |||||||||||

Working Condition:

Max. Head: 190 m

Max. Flow: 3780 m³/h

Max. Liquid temperature: 80°c

Speed: 1480/2980 rpm at 50Hz

Max. Working pressure: 16 bar as standard

Materials:copper, cast iron, ductile iron, 316 stainless steel, 416; 7 rust steel, two-way steel, Hastelloy, Monel, titanium alloy and No. 20 alloy.

Design features:

• The inlet and outlet flanges of the pump body are all located in the lower pump body, so that the rotor can be taken out without disassembling the system pipeline, which is convenient for maintenance. Part of the pump body adopts dual-channel design to reduce the radial force, thereby extending the mechanical seal and bearing life.

• The hydraulic design of the impeller of the split pump adopts the most advanced CFD technology, thus improving the hydraulic efficiency of the OJS pump. The impeller is dynamically balanced to ensure the smooth operation of the OJS pump.

• The shaft diameter is thicker and the bearing spacing is short, which reduces the shaft deflection and prolongs the life of the mechanical seal and the bearing. The shaft sleeve can be made of many different materials to prevent the shaft from being corroded and worn, and the shaft sleeve can be replaced.

• Wear ring The replaceable wear ring is used between the pump body and the impeller to prevent the wear of the center-split pump body and the impeller. It is convenient to replace and low in maintenance costs. At the same time, it ensures the running clearance and high work efficiency. Either packing or mechanical seal can be used, and the sealing device can be replaced without removing the pump cover.

• The suction port and discharge port of the horizontal double-suction centrifugal pump are below the pump shaft line, and are perpendicular to the axis. All parts can be removed by uncovering the pump cover during maintenance without disassembling the motor and pipeline.

Max. Head: 190 m

Max. Flow: 3780 m³/h

Max. Liquid temperature: 80°c

Speed: 1480/2980 rpm at 50Hz

Max. Working pressure: 16 bar as standard

Materials:copper, cast iron, ductile iron, 316 stainless steel, 416; 7 rust steel, two-way steel, Hastelloy, Monel, titanium alloy and No. 20 alloy.

Design features:

• The inlet and outlet flanges of the pump body are all located in the lower pump body, so that the rotor can be taken out without disassembling the system pipeline, which is convenient for maintenance. Part of the pump body adopts dual-channel design to reduce the radial force, thereby extending the mechanical seal and bearing life.

• The hydraulic design of the impeller of the split pump adopts the most advanced CFD technology, thus improving the hydraulic efficiency of the OJS pump. The impeller is dynamically balanced to ensure the smooth operation of the OJS pump.

• The shaft diameter is thicker and the bearing spacing is short, which reduces the shaft deflection and prolongs the life of the mechanical seal and the bearing. The shaft sleeve can be made of many different materials to prevent the shaft from being corroded and worn, and the shaft sleeve can be replaced.

• Wear ring The replaceable wear ring is used between the pump body and the impeller to prevent the wear of the center-split pump body and the impeller. It is convenient to replace and low in maintenance costs. At the same time, it ensures the running clearance and high work efficiency. Either packing or mechanical seal can be used, and the sealing device can be replaced without removing the pump cover.

• The suction port and discharge port of the horizontal double-suction centrifugal pump are below the pump shaft line, and are perpendicular to the axis. All parts can be removed by uncovering the pump cover during maintenance without disassembling the motor and pipeline.