TLJ Ceramics Desulfurization Pump

TLJ Ceramics Desulfurization Pump is a high-flow, low-lift, cantilever single-stage Centrifugal pump. Especially suitable for conveying strong Abrasive, strong corrosive medium. The core technology is based on high-efficiency hydraulic model of metal pump, using CFD design method and solid-liquid two-phase flow hydraulic design method, creating “ceramic + metal” composite manufacturing process.

TLJ Ceramics Desulfurization Pump is especially suitable for the transport of acid, corrosive ore slurry, slurry electrolyte, sewage and other medium in wet smelting of lead, zinc, gold, silver, copper, manganese, cobalt and rare earth etc. They are also used in processes such as ammonia phosphate and titanium dioxide (TiO2) pigment production, salt solution mining, sugar beet processing and sea water desalination.

TLJ Ceramics Desulfurization Pump is especially suitable for the transport of acid, corrosive ore slurry, slurry electrolyte, sewage and other medium in wet smelting of lead, zinc, gold, silver, copper, manganese, cobalt and rare earth etc. They are also used in processes such as ammonia phosphate and titanium dioxide (TiO2) pigment production, salt solution mining, sugar beet processing and sea water desalination.

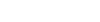

tructure Drawing of Type Sproull® TLJ Pump

| 1 | impeller | 6 | exit tube | 11 | remove ring | 16 | pump shaft | 21 | coupling |

|---|---|---|---|---|---|---|---|---|---|

| 2 | spiral case | 7 | o-ring | 12 | retaining plate | 17 | rear bearing | 22 | plinth |

| 3 | rear guard | 8 | o-ring | 13 | front bearing gland | 18 | bearing case | 23 | bracket body |

| 4 | sealing body | 9 | o-ring | 14 | front bearing | 19 | rear bearing gland | 24 | bracket cover |

| 5 | inlet short tube | 10 | mechanical seal (or packing seal) | 15 | oil standard | 20 | coupling housing |

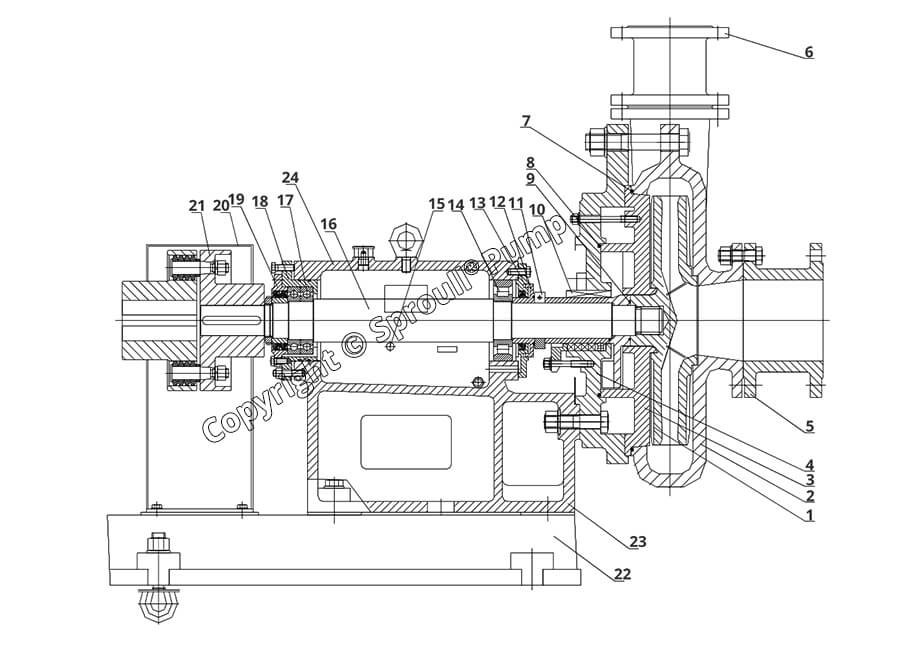

Sproull® TLJ Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| 150TLJ-35 | |||

| 150 | Outlet diameter(mm) | ||

| TLJ | Horizontalversion desulfurization pumps | ||

| 35 | EXternal diameter of impeller(cm) | ||

Sproull® TLJ Preformance parameter list

| Type |

Speed n(r/min) |

Capacity Q(m³/h) |

Head H(m) |

Eff η(%) |

Shaft power pa(kw) |

Motor power kw/V |

NPSH r(m) |

|---|---|---|---|---|---|---|---|

| 40TLJ-30 | 1460 | 34 | 36.3 | 43.1 | 7.8 | 11/380 | 1.6 |

| 55 | 31.9 | 48.5 | 9.9 | 15/380 | |||

| 78 | 26.4 | 45.4 | 12.4 | 18.5/380 | |||

| 50TLJ-40 | 1470 | 33 | 51.7 | 35.4 | 13.1 | 18.5/380 | 2.5 |

| 68 | 43.4 | 45.1 | 17.8 | 30/380 | |||

| 76 | 40.8 | 44.7 | 18.9 | 30/380 | |||

| 65TLJ-40 | 1480 | 71 | 63.2 | 46.7 | 26.2 | 37/380 | 4.5 |

| 141 | 57.5 | 62.1 | 35.6 | 45/380 | |||

| 159 | 54.6 | 62.1 | 38.1 | 55/380 | |||

| 80TLJ-36 | 1480 | 86 | 47.1 | 47.4 | 23.3 | 30/380 | 3.2 |

| 151 | 42 | 60.7 | 28.5 | 37/380 | |||

| 167 | 39.9 | 62 | 29.3 | 37/380 | |||

| 100TLJ-35 | 1480 | 163 | 45.9 | 60.9 | 33.5 | 45/380 | 4.1 |

| 278 | 41.5 | 71.9 | 43.7 | 55/380 | |||

| 323 | 39.2 | 73.2 | 47.1 | 75/380 | |||

| 150TLJ-55 | 990 | 280 | 53.7 | 63.2 | 64.8 | 90/380 | 3.7 |

| 517 | 48 | 76.5 | 88.3 | 110/380 | |||

| 630 | 45.9 | 78.1 | 100.8 | 132/380 | |||

| 200TLJ-45 | 990 | 279 | 31 | 62.9 | 37.4 | 55/380 | 3.3 |

| 557 | 26.1 | 80.8 | 49 | 75/380 | |||

| 645 | 23.3 | 77.8 | 52.6 | 75/380 | |||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

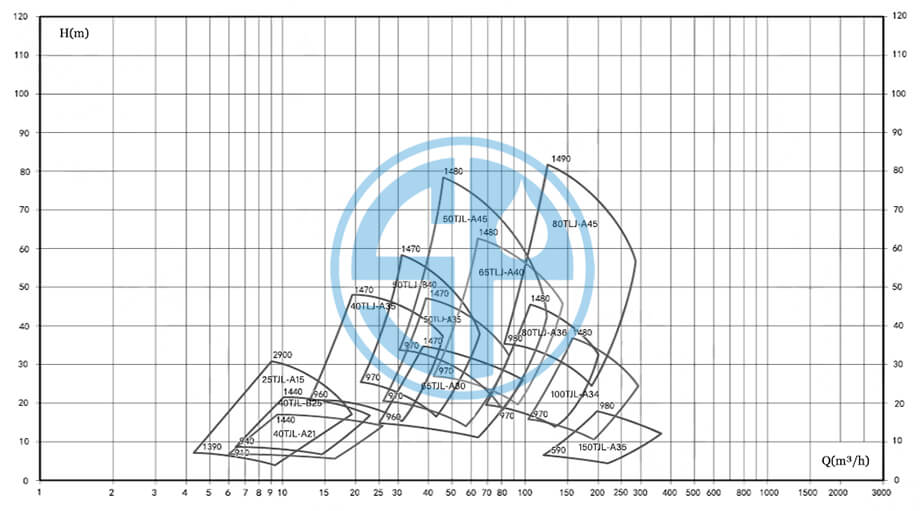

Sproull® TLJ Installation Drawing(Demonstration)

| Type | Motor | Installation Dimensions(mm) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | H1 | H2 | Inlet flange | Outlet flange | |||||||||||||

| power(kw) | volt | a1 | a2 | a3 | a4 | a5 | m-Φ1 | b1 | b2 | b3 | b4 | b5 | n-Φ1 | ||||||||||

| 100TLJ-46 | 110 | 380 | 1650 | 290 | 318 | 700 | 700 | 100 | 260 | 548 | 500 | 285 | 240 | 211 | 150 | 20 | 8-Φ22 | 220 | 180 | 156 | 100 | 20 | 8-Φ18 |

Working Condition:

Value of PH:2.5-13

Concentration of chlorion:≤60000 ppm

Weight density:≤60%

Temperature of medium:≤120℃

Design features:

• Pump Shell and pump cover are lined with silicon carbide ceramics, external metal armored, pump overall reliability, safety, easy disassembly and assembly.

• The impeller is built-in metal hub structure, and the outer silicon carbide ceramic material is manufactured as a whole. The mechanical strength, Abrasion Resistance and corrosion resistance of the impeller are basically guaranteed.

• Convenient maintenance and low maintenance cost. Easy to repair, ceramic parts damaged, according to the circumstances on-site or back to the manufacturer for repair, without the whole part scrap treatment, greatly reduce maintenance costs and time.

Value of PH:2.5-13

Concentration of chlorion:≤60000 ppm

Weight density:≤60%

Temperature of medium:≤120℃

Design features:

• Pump Shell and pump cover are lined with silicon carbide ceramics, external metal armored, pump overall reliability, safety, easy disassembly and assembly.

• The impeller is built-in metal hub structure, and the outer silicon carbide ceramic material is manufactured as a whole. The mechanical strength, Abrasion Resistance and corrosion resistance of the impeller are basically guaranteed.

• Convenient maintenance and low maintenance cost. Easy to repair, ceramic parts damaged, according to the circumstances on-site or back to the manufacturer for repair, without the whole part scrap treatment, greatly reduce maintenance costs and time.