QS Submersible Sewage Pump

QS Submersible Sewage Pump is a new type of pump which has been developed by combining the characteristics of submersible pumps at home and abroad. In the discharge of solid particles and long fiber waste, has a unique effect.

The pump adopts unique impeller structure and a new type of mechanical seal, which can effectively input and deliver solids and long fibers. Compared with the traditional impeller, the pump impeller adopts the form of single channel or double channel. It is similar to a curved pipe with the same section size. It has very good over-flow property and is matched with a reasonable volute chamber, the pump has the advantages of high efficiency, dynamic and static balance test of Impeller, and no vibration in operation.

QS Submersible Sewage Pump is widely used to transport the wastewater, sewage with particles and fibres in chemical pharmaceutical, mining, papermaking, cement, steel, power generation, coal processing industry and city sewage treatment plant water supply and drainage system, municipal engineering and construction sites etc., and also be used to pump water and corrosive medium.

The pump adopts unique impeller structure and a new type of mechanical seal, which can effectively input and deliver solids and long fibers. Compared with the traditional impeller, the pump impeller adopts the form of single channel or double channel. It is similar to a curved pipe with the same section size. It has very good over-flow property and is matched with a reasonable volute chamber, the pump has the advantages of high efficiency, dynamic and static balance test of Impeller, and no vibration in operation.

QS Submersible Sewage Pump is widely used to transport the wastewater, sewage with particles and fibres in chemical pharmaceutical, mining, papermaking, cement, steel, power generation, coal processing industry and city sewage treatment plant water supply and drainage system, municipal engineering and construction sites etc., and also be used to pump water and corrosive medium.

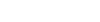

tructure Drawing of Type Sproull® QS Pump

| 1 | Plinth | 8 | Shaft | 15 | Bearing inner ring gland | 22 | Outlet pipe | 29 | Machine seal seat |

|---|---|---|---|---|---|---|---|---|---|

| 2 | Front pump cover | 9 | Motor | 16 | Upper gland | 23 | Power cable | 30 | Back wear ring |

| 3 | Casing | 10 | Rotor | 17 | Upper bearing case | 24 | Cable pressure plate | 31 | Impeller key |

| 4 | Guide vane | 11 | Outer tube | 18 | Wiring board | 25 | Cable sheath | 32 | Impeller |

| 5 | Auxiliary impeller | 12 | Shaft sleeve | 19 | Junction Box | 26 | Cable seal | 33 | Front wear ring |

| 6 | Machine seal | 13 | Lower gland | 20 | Terminal | 27 | Thrust bearing gland | 34 | Impeller baffle |

| 7 | Lower bearing case | 14 | Upper bearing | 21 | Top cover | 28 | Thrust bearing |

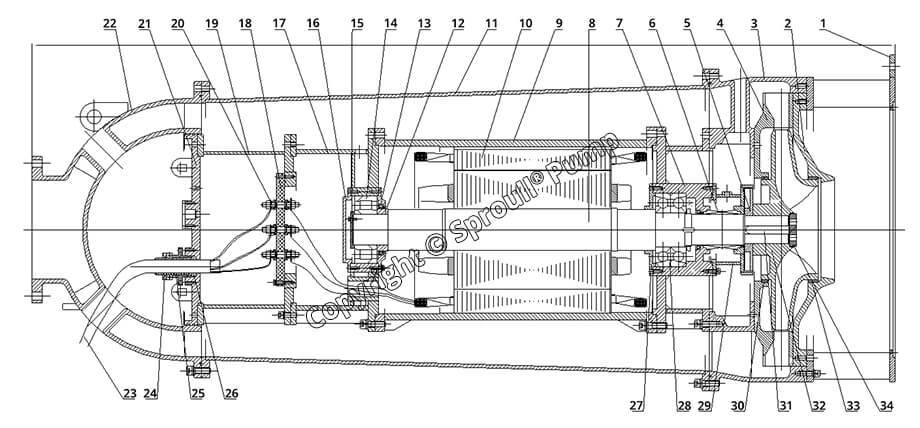

Sproull® QS Preformance Curve

| lllustrations of Model Type | |||

|---|---|---|---|

| 200QS250-110-160 | |||

| 200 | Discharge caliber(mm) | ||

| QS | Submersible Sewage Pump | ||

| 250 | Capacity(m³/h) | ||

| 110 | Head(m) | ||

| 160 | Power of fitted motor(kW) | ||

Sproull® QS Preformance parameter list

| Type |

Capacity m³/h |

Head m |

Speed n(r/min) |

Eff η(%) |

Motor power kw |

|---|---|---|---|---|---|

| 100QS200-55-55 | 200 | 55 | 1450 | 64 | 55 |

| 150QS300-80-132 | 300 | 80 | 1450 | 60 | 132 |

| 200QS500-60-160 | 500 | 60 | 1450 | 70 | 160 |

| 250QS750-60-200 | 750 | 60 | 1450 | 79 | 200 |

| 300QS1440-35-220 | 1440 | 35 | 980 | 80 | 220 |

| 350QS1800-12-90 | 1800 | 12 | 980 | 80 | 90 |

| 400QS2000-30-250 | 2000 | 30 | 980 | 82 | 250 |

| 500QS4000-20-315 | 3000 | 25 | 740 | 82 | 315 |

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||

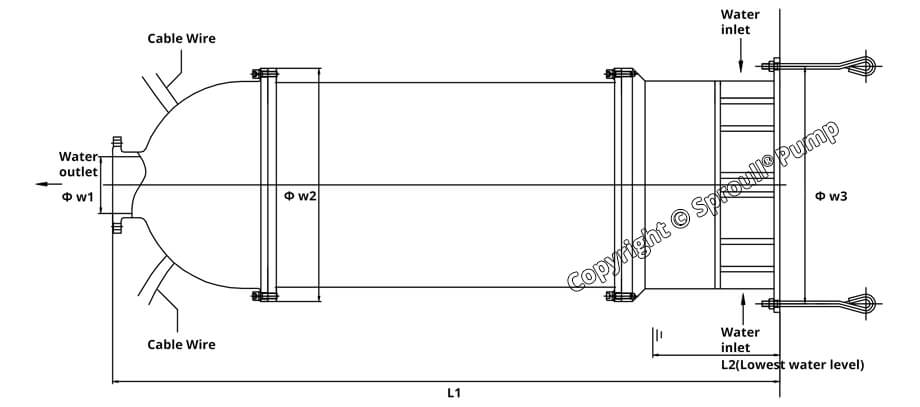

Sproull® QS Installation Drawing(Demonstration)

| Type | Motor | Installation Dimensions(mm) | |||||

|---|---|---|---|---|---|---|---|

| L1 | L2 | Φ w1 | Φ w2 | Φ w3 | |||

| power(kw) | volt | ||||||

| 200QS220-120-160 | 160 | 380 | 2361 | 450 | 200 | 825 | 840 |

Working Condition:

Rated voltage:380V, also can use 200-660V,3KV,6KV,10KV.

Frequency:50Hz or 60Hz three-phase AC power supply.

Medium temperature:≤40℃, Max. deep:≤20m, pH:4~10.

Medium density:≤1150Kg/m3.

Solid phase volume ratio:≤5%.

Design features:

1. Adopt the design of anti-clogging hydraulic component with large passage, greatly improve the ability of sewage to pass through the 5 times fiber material of pump caliber and the solid particles with the diameter of pump about 50% .

2. The design is reasonable, the matching motor is reasonable, the efficiency is high, the energy conservation effect is remarkable.

3. The mechanical seal is made of hard and corrosion-resistant Tungsten Carbide, which is durable and wear-resistant. It can make the pump run more than 8000 hours.

4. The pump structure is compact, the volume is small, the movement is convenient, the installment is simple, does not need to build the pump house, dives in the water can work, reduces the project cost greatly.

5. The oil-water probe is set in the pump oil room. When the mechanical seal of the pump side machine is broken, the water enters the oil room and the probe gives a signal to protect the pump.

6. Can Be equipped with automatic safety protection control cabinet according to User’s need, to monitor and control the leakage of water, leakage of electricity, overload and over-temperature of the pump, so as to ensure reliable and safe operation of the pump.

7. Ensure that the motor is not overloaded within the operating range of the head.

8. According to the use of motor can use water jacket type internal circulation cooling system, can ensure that the pump in the water (dry) state safe operation.

9. There are two ways of installation: fixed automatic coupling installation and mobile free installation, which can meet the needs of different occasions.

Rated voltage:380V, also can use 200-660V,3KV,6KV,10KV.

Frequency:50Hz or 60Hz three-phase AC power supply.

Medium temperature:≤40℃, Max. deep:≤20m, pH:4~10.

Medium density:≤1150Kg/m3.

Solid phase volume ratio:≤5%.

Design features:

1. Adopt the design of anti-clogging hydraulic component with large passage, greatly improve the ability of sewage to pass through the 5 times fiber material of pump caliber and the solid particles with the diameter of pump about 50% .

2. The design is reasonable, the matching motor is reasonable, the efficiency is high, the energy conservation effect is remarkable.

3. The mechanical seal is made of hard and corrosion-resistant Tungsten Carbide, which is durable and wear-resistant. It can make the pump run more than 8000 hours.

4. The pump structure is compact, the volume is small, the movement is convenient, the installment is simple, does not need to build the pump house, dives in the water can work, reduces the project cost greatly.

5. The oil-water probe is set in the pump oil room. When the mechanical seal of the pump side machine is broken, the water enters the oil room and the probe gives a signal to protect the pump.

6. Can Be equipped with automatic safety protection control cabinet according to User’s need, to monitor and control the leakage of water, leakage of electricity, overload and over-temperature of the pump, so as to ensure reliable and safe operation of the pump.

7. Ensure that the motor is not overloaded within the operating range of the head.

8. According to the use of motor can use water jacket type internal circulation cooling system, can ensure that the pump in the water (dry) state safe operation.

9. There are two ways of installation: fixed automatic coupling installation and mobile free installation, which can meet the needs of different occasions.