QZJ Heavy duty Submersible Slurry Pump

QZJ Heavy duty Submersible Slurry Pump is a high-lift dewatering pump and submersible slurry pump,It can decompose and resuspension settled or compacted solids, allowing them to easily transfer a high percentage of solids into water.

QZJ Heavy duty Submersible Slurry Pump is widely used in mining, power, metallurgy, coal, environmental protection and other industries conveying slurry containing abrasive solid particles. Such as metallurgical ore dressing plant slurry transport, thermal power plant hydraulic ash removal, coal washing plant slurry and heavy medium transport, dredging river, river dredging, etc. . In the chemical industry, it is also possible to transport some corrosive slurries containing crystals.

QZJ Heavy duty Submersible Slurry Pump is widely used in mining, power, metallurgy, coal, environmental protection and other industries conveying slurry containing abrasive solid particles. Such as metallurgical ore dressing plant slurry transport, thermal power plant hydraulic ash removal, coal washing plant slurry and heavy medium transport, dredging river, river dredging, etc. . In the chemical industry, it is also possible to transport some corrosive slurries containing crystals.

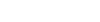

Structure Drawing of Type Sproull® QZJ Pump

| 1 | Submersible motors | 4 | Mechanical seal seat | 7 | Bottom | 10 | Rearguard |

|---|---|---|---|---|---|---|---|

| 2 | Shaft sleeve | 5 | Pump body | 8 | Gland | 11 | Bearing gland |

| 3 | Mechanical seal | 6 | Impeller | 9 | Mixing wheel |

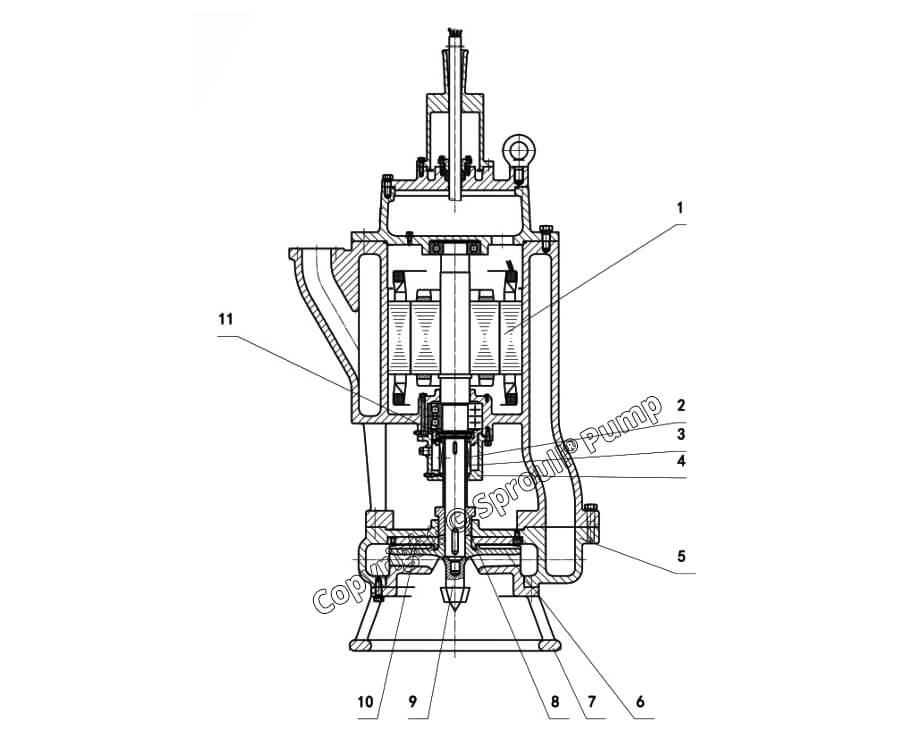

Sproull® QZJ Preformance Curve

Sproull® QZJ Preformance parameter list

| Type | Maximum weight of the slurry solids concentration | The largest proportion of slurry | Maximum size of the solid particles | Highest slurry temperature | Maximum flow rate value | Highest lift(kg pressure) | Maximum diving attempt |

|---|---|---|---|---|---|---|---|

| 80QZJ | 0.65 | 2.7 | 25mm | 90℃ | 130 |

35m (3.5bar) |

28mm |

| 80AQZJ | 0.65 | 2.7 | 32mm | 90℃ | 220 |

37m (3.7bar) |

28mm |

| 80HQZB | 0.4 | 2.7 | 12mm | 90℃ | 100 |

55m (5.5bar) |

28mm |

| 100QZJ | 0.65 | 2.7 | 30mm | 90℃ | 350 |

23m (2.3bar) |

28mm |

| 100AQZJ | 0.65 | 2.7 | 35mm | 90℃ | 430 |

35m (3.5bar) |

28mm |

| 100HQZB | 0.4 | 2.7 | 20mm | 90℃ | 270 |

60m (6.0bar) |

28mm |

| 150QZJ | 0.65 | 2.7 | 40mm | 90℃ | 550 |

25m (2.5bar) |

28mm |

| 150AQZJ | 0.65 | 2.7 | 40mm | 90℃ | 760 |

38m (3.8bar) |

28mm |

| 150HQZB | 0.4 | 2.7 | 22mm | 90℃ | 380 |

60m (6.0bar) |

28mm |

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||

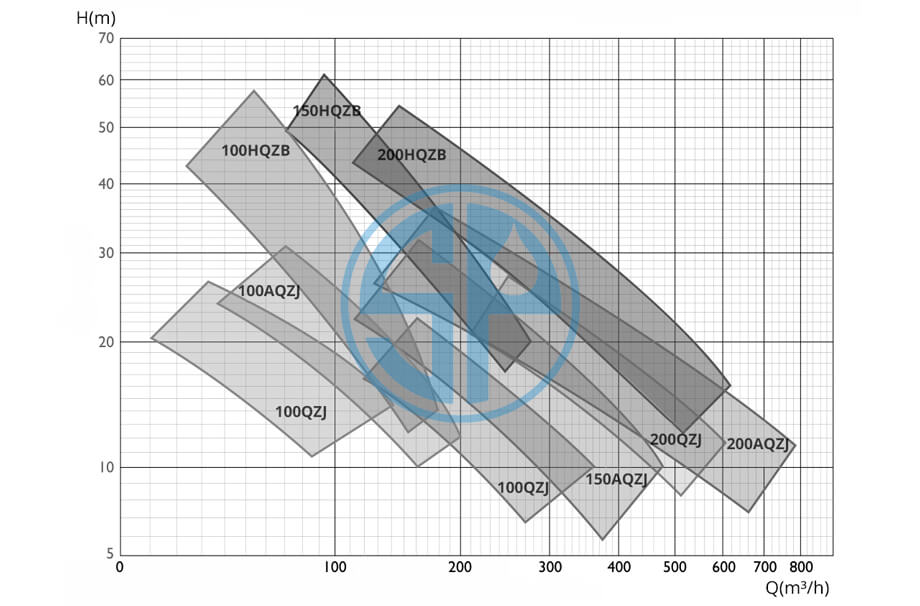

Sproull® QZJ Installation Drawing(Demonstration)

| Type | Motor power | Clear water performance | Dimensions mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kw) | Capacity Q | Head H | Speed n | Max particle | Outlet Dia. | A | B | C | D | E | |

| ( m3/h) | ( m) | (rpm) | (mm) | (mm) | |||||||

| 150QZJ | 90 | 380 | 25 | 960 | 30 | 150 | 1775 | 1120 | 490 | 705 | 630 |

Working Condition:

Capacity: 130~600 m³/h

Head: 33-60 m

Speed:960~1450 r/min

Design features:

• A motor enclosure which eliminated electrical motor heating and burnout.

• A motor with reserves of power to enable direct online starting when in settled sump solids.

• Design an integral inducer to break down and re-suspend settled solids.

• Develop a mechanical sealing system which was not subjected to the pumped media pressure.

• Create a cable gland entry and motor configuration which kept the terminal enclosure separate from the motor enclosure.

Capacity: 130~600 m³/h

Head: 33-60 m

Speed:960~1450 r/min

Design features:

• A motor enclosure which eliminated electrical motor heating and burnout.

• A motor with reserves of power to enable direct online starting when in settled sump solids.

• Design an integral inducer to break down and re-suspend settled solids.

• Develop a mechanical sealing system which was not subjected to the pumped media pressure.

• Create a cable gland entry and motor configuration which kept the terminal enclosure separate from the motor enclosure.