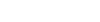

ZMJ Slurry Pump is horizontal, cantilever, double casing, single-stage and single-suction centrifugal slurry pump. By internationally advanced solid-liquid two phase flow theory, our company newly designed this series of anti-abrasion and corrosion resistant slurry pump based on the principle of minimum hydraulic loss and abrasion. The fact that geometry of pump wet parts come in line with flowing state of pumped medium contributes to the reduction of local and whole coursehydraulic loss due to vortex and flow impact. Consequently, the abrasion of wet parts can be mitigated. The pump series have following benefits: complete range of specifications and performance, novel structure, high efficiency and energy conservation, low vibration, reliable operation, long service life, easy installation and maintenance etc.

Design, manufacture and quality of this series conform to Standard JB/T8096 Centrifugal slurry pumps.

ZMJ Slurry Pump is widely apply to mines, metallurgy, power, coal, chemical engineering, building materials and flue gas desulphurization peripheral system etc., and are used for delivering slurry with abrasive particles or corrosive slurry.

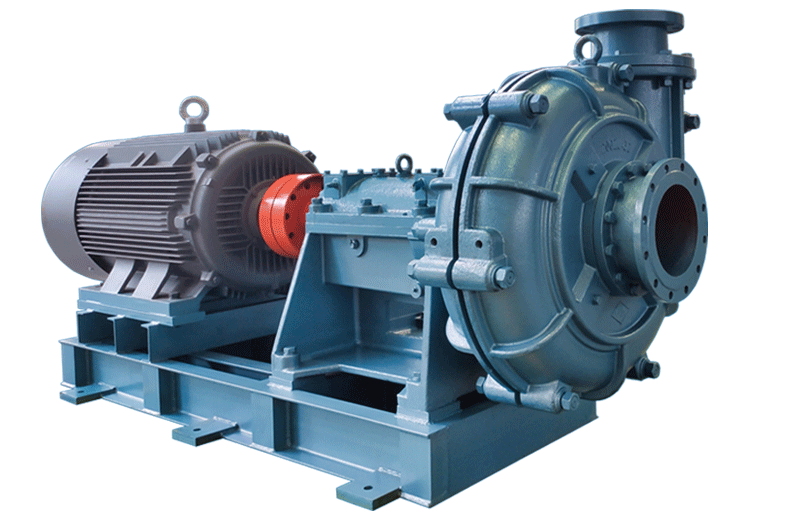

Structure Drawing of Type Sproull® ZMJ Slurry Pump

| 1 | motor | 8 | rear bearing | 15 | front bearing | 22 | the stuffing box | 29 | oil seals |

|---|---|---|---|---|---|---|---|---|---|

| 2 | pump | 9 | rear bearing cap | 16 | the tray cover | 23 | the seal ring | 30 | the outlet tube |

| 3 | the Coupling guard | 10 | oil seals | 17 | the oil standard | 24 | the filler | 31 | the pump casing |

| 4 | the ITU | 11 | the spacer sleeve | 18 | the axis | 25 | the packing gland | 32 |

water absorption short tude |

| 5 | pin | 12 | nut | 19 |

after the pump shell |

26 | the sleeve | 33 | impeller |

| 6 | the base | 13 | the bracket body | 20 |

the rear retaining plate |

27 | demolition rings | 34 | Guard plate |

| 7 | bearing box | 14 | front bearing cap | 21 |

one pair of impellers |

28 | the drip ring | 35 | the volute |

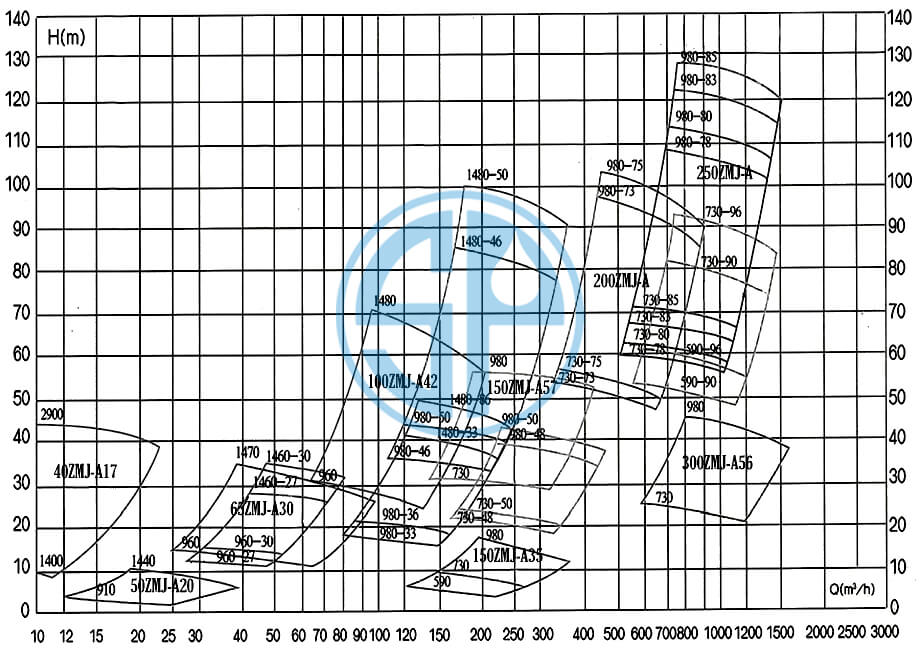

Sproull® ZMJ Preformance Curve

Note:Approximate clear water performance for preimnary pump selection only.

| Type Designation of ZMJ Slurry Pumps | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 200ZMJ-I-A60 | 200ZMJ-I-A60 | ||||||||

| 200 | Outlet diameter(mm) | ||||||||

| Z | Slurry pump | ||||||||

| M | High chromium | ||||||||

| I | I denoted the first stage pump or single stage pump | ||||||||

| A | Numbers of the vanes of impeller | ||||||||

| 60 | External diameter of impeller(cm) | ||||||||

| K | Opening model impeller | ||||||||

| Symbol | A | B | C | D | E | F | G | …… | |

| Numbers of the vanes | 5 | 4 | 3 | 2 | 1 | 6 | 7 | …… | |

Sproull® ZMJ Preformance parameter list

| Type |

Max.Power (kw) |

Clear water performance |

Impeller Vane No. |

Patricle max.sixe handled occasionally (mm) |

Weight (kg) |

||||

|---|---|---|---|---|---|---|---|---|---|

| Capacity Q | Head H | Speed n | Eff.η | NPSH | |||||

| ( m3/h) | ( m) | (rpm) | (%) | (m) | |||||

| 40ZMJ-A-A17 | 7.5 | 4-23 | 9.0-44.6 | 1400-2900 | 52.4 | 2.5 | 5 | 11 | 121(127) |

| 40ZMJ-A-AK17 | |||||||||

| 50ZMJ-I-A33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 44.7 | 1.4 | 5 | 13 | 537(545) |

| 50ZMJ-I-AK33 | |||||||||

| 65ZMJ-I-A30 | 11 | 20-71 | 6.0-28.2 | 700-1480 | 61.5 | 1.8 | 5 | 19 | 500(508) |

| 65ZMJ-I-AK30 | |||||||||

| 80ZMJ-I-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 | 67.7 | 2.5 | 5 | 24 | 980(926) |

| 80ZMJ-I-AK36 | |||||||||

| 150ZMJ-I-A50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 76.8 | 2.5 | 5 | 48 | 1735(1468) |

| 150ZMJ-I-AK50 | |||||||||

| 200ZMJ-I-A65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 79.6 | 2.5 | 5 | 62 | 2323 |

| 200ZMJ-I-AK65 | |||||||||

| 250ZMJ-I-A73 | 500 | 292-1441 | 19.7-92.4 | 490-980 | 76.5 | 3.0 | 5 | 72 | 3466 |

| 250ZMJ-I-AK73 | |||||||||

| 300ZMJ-I-A85 | 450 | 477-1742 | 18.9-71.3 | 400-730 | 79.8 | 3.8 | 5 | 85 | 4965 |

| 300ZMJ-I-AK85 | |||||||||

| 350ZMJ-I-A95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 78.1 | 3.0 | 5 | 88 | 5220 |

| 350ZMJ-I-AK95 | |||||||||

| 400ZMJ-I-A125 | 1200 | 2520-5040 | 48-66 | 200-500 | 80 | 4.5-9 | 5 | 110 | 14432 |

| 400ZMJ-I-AK125 | |||||||||

| 450ZMJ-I-A140 | 1200 | 3310-6610 | 52-57 | 200-490 | 85 | 5-10 | 5 | 120 | 18864 |

| 450ZMJ-I-AK140 | |||||||||

| 500ZMJ-I-A140 | 1200 | 3750-7960 | 49-55.2 | 200-490 | 82 | 5-10 | 5 | 120 | 19100 |

| 500ZMJ-I-AK140 | |||||||||

|

Only part of the product model demonstration If the actual requirements of performance parameters and performance table does not match, can be based on user requirements for design and manufacture. |

|||||||||

Note: 1.(NPSH)r means the stall speed of the sample, the second is the value of the specified point. 2. The normal size by 56% to allow for the maximum size of the intermittent pass. 3. The weight of the pump column, there is a common base for the two values of the pump. 4. The efficiency refers to the value when packing shaft seal is used. Among them Outside the brackets for high-speed data pump weight parameters, with brackets For the low speed pump weight.

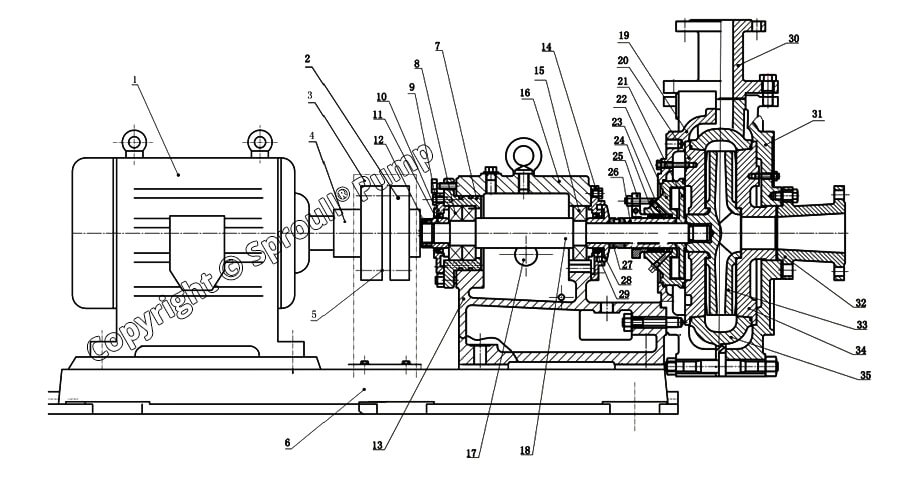

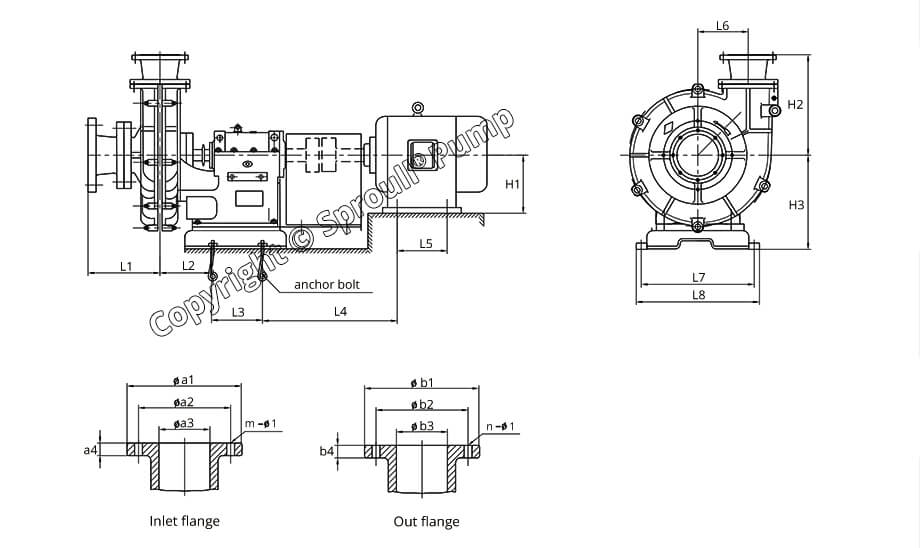

Sproull® ZMJ Installation Drawing(Demonstration)

| Type | Installation Dimensions(mm) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | H1 | H2 | H3 | Inlet flange | Outlet flange | |||||||||

| a1 | a2 | a3 | a4 | m-Φ1 | b1 | b2 | b3 | b4 | n-Φ1 | ||||||||||||

| 250ZMJ-I-A70 | 458 | 465 | 630 | 1195 | 1250*900 | 520 | 1020 | 1120 | 500 | 898 | 910 | 460 | 410 | 300 | 42 | 12-Φ26 | 425 | 370 | 250 | 34 | 12-Φ30 |

Capacity: 4-7960 m³/h

Head: 1.4-130 m

Handing solids: 0-120 mm

Concentration: 0%-70%

Power:4~1200 kw

Working Temperature:≤105℃

Max Weight Concentration of Allowable Transferred Solid-liquid Mixture: Mortar(Slurry) and Coal Slurry≤45%、Pulp and Dense Medium≤60%.

Series: Two stages and multistage series connection, need toconfirm with technical department if more than two stages.

Materials: Hyper chrome alloy, Rubber, Polyurethane, Ceramic, Stainless steel etc.

Design features:

1. Adopting modern CAD design method, the hydraulic performance is excellent, the efficiency is high and the wear rate is low.

2. Wide Runner, good anti-clogging performance, excellent cavitation performance.

3. Axial inlet, radial outlet, outlet direction can be installed by rotating eight angles.

4. Adopt double pump shell structure design, split pump Shell for bearing pressure, lining for wear resistance.

5. Interchangeable metal lining and rubber lining, the impeller also has metal and rubber two materials.

6. The bearing assembly is designed with short cantilever and large shaft diameter to minimize deviation and vibration.

7. Various types of shaft seal: Packing Seal, Auxiliary Impeller Power Seal, mechanical seal and various special combination seal.

8. within the allowable pressure can be used in series.